Zeolites such as ZSM-5 are essential components in industrial catalysis, with widespread applications in petroleum refining, coal conversion, and environmental remediation.

In practice, industrial catalysts typically consist of both "zeolitic components" and "non-zeolitic components" (e.g., silica, alumina, amorphous aluminosilicate, clays), which together play important roles in processes like polyolefin catalytic cracking and residue fluid catalytic cracking. However, most research to date has focused mainly on the diffusion behaviors of a single zeolitic component or non-zeolitic component, neglecting the interfacial interactions between them.

In a study published in the Journal of the American Chemical Society, a research team led by Prof. XU Shutao, Prof. WEI Yingxu, and Prof. LIU Zhongmin from theDalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. YAN Zifeng's team from China University of Petroleum (East China), investigated the diffusion and cracking kinetics of zeolite-based multicomponent model catalysts.

The researchers designed a series of model cracking catalysts composed of ZSM-5 and mesoporous SiO2 with precisely controlled interfacial channel connectivity. These catalysts enabled systematic exploration of structure–diffusion–reaction relationships at zeolite and non-zeolite interfaces. By employing advanced characterization techniques—including hyperpolarized (HP) 129Xe nuclear magnetic resonance (NMR), intelligent gravimetric analysis (IGA), and time-resolved in situ Fourier-transform infrared (FTIR) spectroscopy—the researchers quantitatively analyzed both global and zeolitic diffusion behaviors in these multicomponent systems.

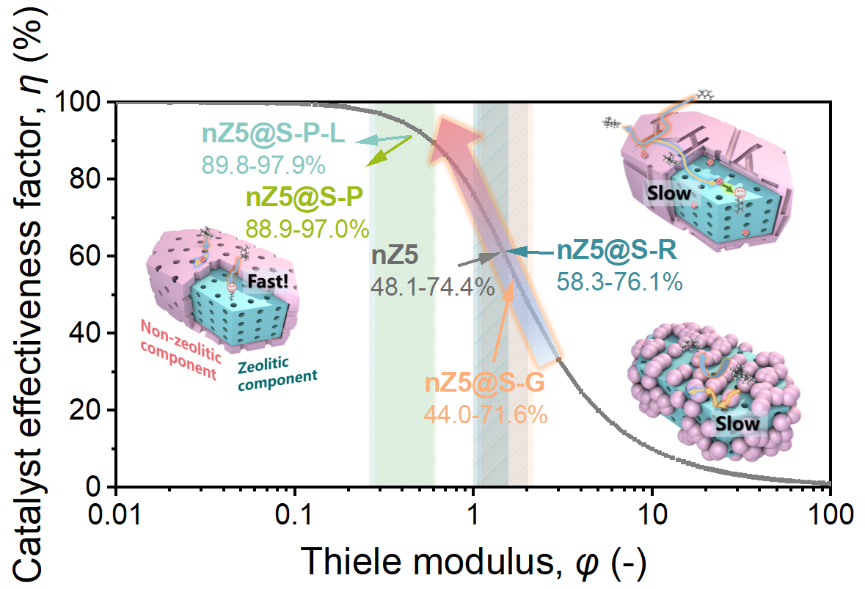

Their findings revealed a pronounced "funnel effect" from the mesopores in non-zeolitic component, showing that a well-connected micro-/mesopore network can effectively accelerate interfacial diffusion and fully enhance the catalytic efficiency of the zeolitic component. This highlights the foundational functions of pore interconnectivity in facilitating the free migration of reactant species between zeolitic and non-zeolitic components.

"Our study showed that for the elaborate design of industrial multicomponent catalysts, more attention should be placed on constructing highly interconnected hierarchical pore structures—both within and between zeolitic and non-zeolitic components—as well as tuning their surface properties," said Prof. XU.

Catalytic efficiency assessment of multicomponent model catalysts in catalytic cracking of model intermediates(Image by XU Yipu)