Transition metal carbides have attracted much attention due to their unique catalytic properties similar to precious metals. Among them, α-phase molybdenum carbides (α-MoC1-x) shows high activity in activation of water at an ultra-low temperature in water–gas shift and aqueous-phase reforming of methanol reaction.

However, the preparation process of cubic α-MoC1-x generally requires an extra ammonification treatment with high energy-consumption or an assistance by significant amount of precious metals, which severely limits its application.

Recently, a joint research team led by Prof. SUN Jian, Dr. YU Jiafeng, and Dr. LIU Yuefeng from the Dalian institute of chemical physics (DICP) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. Grunwaldt from Karlsruhe Institute of Technology (KIT) of Germany, observed the dynamic evolution of crystal structure at the atomic level, which confirmed that the cubic MoOx phase was the key intermediate for the synthesis of face-centered cubic α-MoC1-x by one-step carburization process.

This work was published in Journal of American Chemical Society on Nov. 23 and was selected as a supplementary cover.

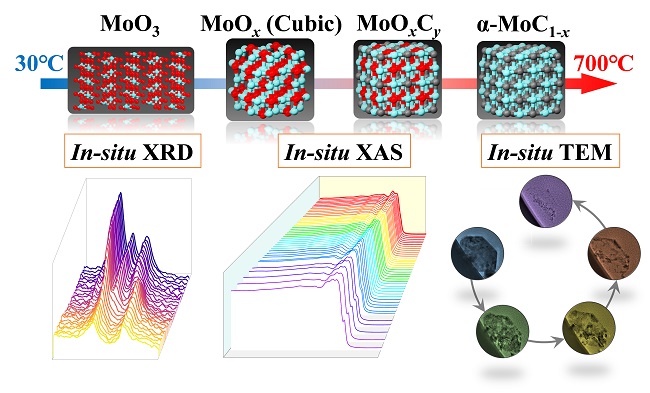

In situ investigations on structural evolutions during the facile synthesis of cubic α-MoC1–x catalysts (Image by YU Jiafeng)

The researchers conducted qualitative and quantitative analyses of crystal phases formed as intermediates during the carburization process, and further monitored the evolution of morphology and crystal structure by environmental transmission electron microscopy.

They found that MoO3 was first reduced to cubic oxygen-deficient Mo oxide (MoOx) at a low temperature (300°C) due to the activation of H2 by a trace amount of Rh. Then, carbon atoms could occupy the oxygen vacancies to form cubic MoOxCy intermediates, which were essential to further transformation to α-MoC1–x via the topological route. The final phase of carbides depended on the primary structure of initial intermediates and the route of structural evolution during the carburization process, where a slow and stepwise reduction was necessary for the formation of active α-MoC1–x.

"This work reveals the key factor of structural evolution during the carburization process," said Prof. SUN. "It provides a more facile and universal strategy for the one-step synthesis of α-MoC1–x." (Text by YU Jiafeng)