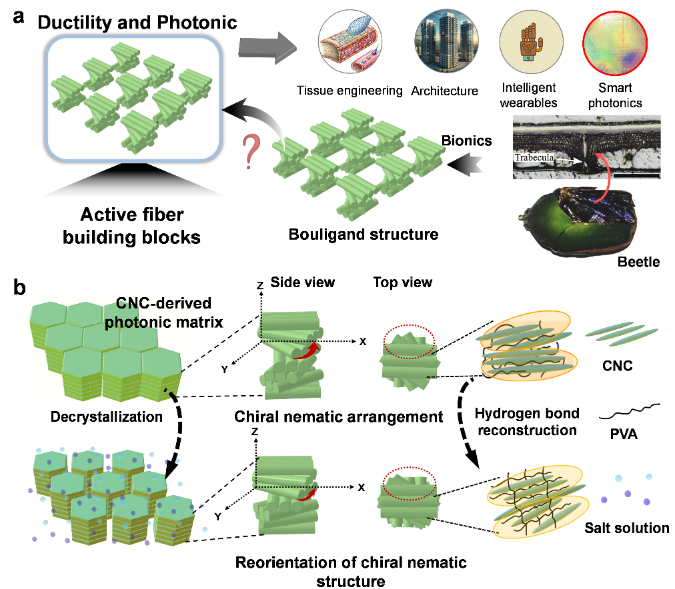

Inspired by the natural Bouligand structure, known for its interlayer coupling and stress transfer mechanisms, researchers are developing advanced materials for a wide range of applications, including impact-resistant bioplastics, ceramic armor, and biomimetic alloy composites. While significant progress has been made in improving the plasticity of materials through molecular-level design and multi-scale structural optimization, most existing materials are still composed of single-scale brittle units. This lack of hierarchical active interfaces and autonomous response capabilities limits their ductility and overall functionality.

To overcome these challenges, researchers aim to develop novel Bouligand-structured materials with multi-level active interfaces, dynamic responsiveness, and enhanced toughness. By balancing micro-movements with structural stability, they seek to resolve the long-standing trade-off between brittleness and toughness, addressing key technical challenges in the practical application of biomimetic materials.

In a recent study published in Materials Today, a research team led by Prof. QING Guangyan from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) has designed and fabricated a high-strength, reconfigurable, and mechanochromic cellulose photonic hydrogel.

The design concept for creating robust hydrogels by transforming the Bouligand structure(Image by LI Qiongya)

By leveraging the self-assembly properties of cellulose nanocrystals (CNCs), the team developed an innovative strategy to construct Bouligand structures with promising applications. This method achieved precise control over the network matrix alignment through nanofiber sliding and hydrogen bond reconstruction, driven by water-activated hydrogen bonding interactions. The resulting photonic hydrogels exhibited impressive mechanical properties, with toughness increasing fivefold (to 155.5 MJ/m³) and stretchability exceeding 950% compared to the original hydrogel.

Additionally, the hydrogels exhibited dynamic color-changing abilities, switching reversibly between red and blue, while maintaining stable electromechanical sensitivity even under repeated stretching. The photonic imaging interface is highly durable and can be reused multiple times, requiring only a five-minute water soak to restore its functionality.

"This work paves a new path for the practical application of CNCs, with potential uses in sustainable bioplastics, flexible electronic substrates, and smart photonic devices," said Prof. QING.