Cellulose nanocrystal (CNC), an emerging bio-based material, has been widely applied in fields like electronics, bioplastics and energy.

However, functional failure of such materials in wet or liquid environments inevitably impairs their development in biomedicine, membrane separation, environmental monitoring, and wearable devices.

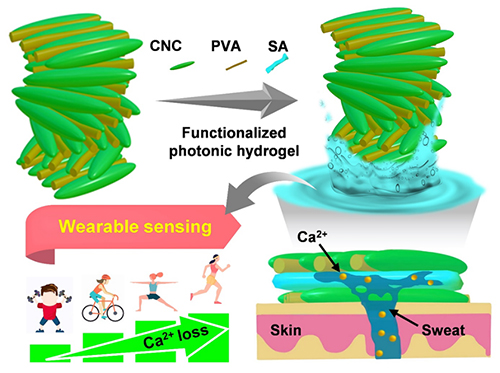

Now, a research group led by Prof. QING Guangyan from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences reported a sustainable, insoluble, and chiral photonic cellulose nanocrystal patch for calcium ion (Ca2+) sensing in sweat.

The study, published in Small on Apr 13, provides a new idea for the functionalization of CNC.

Highly elastic hydrogels constructed by heat-induced hydrogen bond remodeling can switch between wet and dry states (Image by ZHANG Fusheng and LI Qiongya)

The researchers developed a simple and efficient method to fabricate insoluble CNC-based hydrogels. They found that by utilizing intermolecular hydrogen bond reconstruction, thermal dehydration enabled the optimized CNC composite photonic film to form a stable hydrogel network in an aqueous solution. Moreover, they indicated that hydrogel could be reversibly switched between dry and wet states, which was convenient for specific functionalization.

The introduction of functionalized molecules by adsorption swelling in a liquid environment resulted in a hydrogel with freeze resistance (–20°C), strong adhesion, good biocompatibility, and high sensitivity to Ca2+.

"This work is expected to facilitate the application of sustainable cellulose sensors to monitor other metabolites (i.e., glucose, urea, and vitamins, etc.)," said Prof. QING. "It also lays foundation for digitally controlled hydrogel systems operating in environmental monitoring, membrane separations, and wearable devices."