The biorefinery process using renewable biomass such as (hemi) cellulose and lignin as raw materials contributes to the sustainable development of global economy.

Furfural is produced from acid-catalyzed hydrolysis of C5 sugars (xylose). The challenge relies on the low yield and productivity, with high-boiling-point furfural (162°C) being in a diluted aqueous solution.

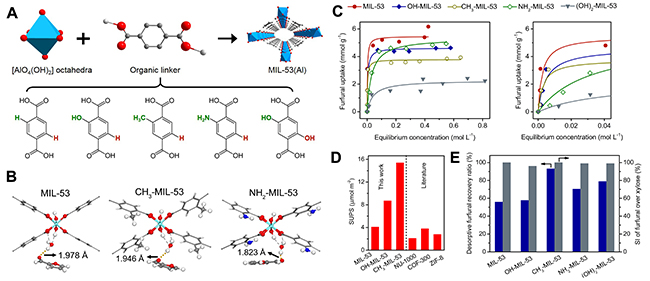

Recently, a group led by Prof. YANG Weishen from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences reported control over the microenvironment of hydrated MIL-53 and isoreticular variants with diversified functional terephthalic acid linkers for the purpose of preferential binding of furfural through delicate host-guest interactions.

The results were published in Angew. Chem. Int. Ed. on Oct. 6.

a) Illustration of MIL‐53 and functional variants decorated with altered linkers. b),c) XRD patterns of the as‐prepared phase (b) and hydrated phase after thermal activation (c). d) Pore size distribution calculated by Horvath‐Kawazoe method (Image by BAN Yujie)

The scientists constructed isoreticular stable MOF materials with diversified functional terephthalic acid linkers. Methyl-bonded hydrated MIL-53 showed highly efficient capture ratio (~98%) in the extremely low concentration of furfural solution (0.5-3 wt.%) and 100% furfural specificity over xylose.

In collaboration with DEND Weiqiao’s group from Shandong University, they identified a distinct "hydrogen-bonding-linkage" between furfural and materials at molecular level by means of detailed DFT calculations, along with gaining binding energy that showed preference of hydrated frameworks to furfural in thermodynamics.

Furthermore, the recovery ratio of furfural reaches ~93% in desorption, was holding promise for recovery of furfural and the recycling of MOF materials in the actual industrials.

This work was supported by National Natural Science Foundation of China. (Text by BAN Yujie)