Molecular sieve membrane-based separation technology, featured with low energy consumption and small carbon footprint, has attracted much attention in gas separation.

Metal-organic frameworks (MOFs) are promising in gas separation membranes due to their diversified structures, high porosity and tailored functionalities. However, defect-free MOF membrane fabrication still remains challenging.

Recently, a research group led by Prof. Yang Weishen and Dr. PENG Yuan from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) has fabricated flexible soft-solid MOF composite membrane on commercial polyvinylidene fluoride (PVDF) substrate.

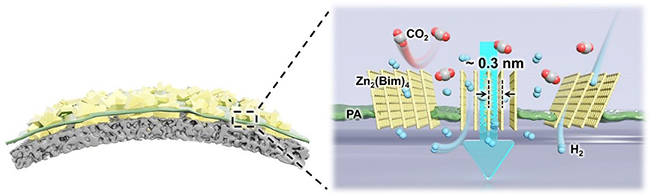

Within the membrane structure, the quasi-vertically oriented, solid Zn2(Benzimidazolate)4 particles grown on PVDF substrate provided predominant molecular sieving gas entrances while soft polyamide eliminated defects enclosing MOF particles, resulting in better performance in H2/CO2 separation.

This work was published in Angew. Chem. Int. Ed. on Feb. 1. It was selected as "Very Important Paper" for achieving high approvals from referees. "Less than 5% of our manuscripts receive such a positive evaluation," said the Editor.

Schematic illustrations of the flexible Zn2(Bim)4 SSCM structure (left) and H2/CO2 separation mechanism through the membrane (right) (Image by SHU Lun)

This robust defect-free composite membrane exhibited an outstanding anti-swelling capacity in condensable feedstock. It showed superior separation accuracies for large C2H6 and C3H8 exclusions.

Moreover, the researchers prepared the Zn2(Bim)4 composite membrane with an ultra-high MOF loading and excellent flexibility. After membrane folding and unfolding at 90° for 50 consecutive times or rolling into a tube with a diameter of 3 mm (the largest bending curvature that MOF membranes can endure), the membrane separation performance remained exactly the same.

Soft-solid Zero Insertion Force(ZIF)-67 and ZIF-8 composite membrane series were also fabricated. Taking advantages of defect elimination, the intrinsic molecular sieving capacities of the MOF particles were given full play.

"The facile fabrication approach benefits industrialized membrane scaling-up. And feasible membranes for specific separation systems can be customized by MOF and polymer modular design strategy," said Prof. YANG.

This work was supported by the National Natural Science Foundation of China. (Text by PENG Yuan)