Research News

-

03 26, 2020Scientists Developed a New Treatment Method by Using Functional Metabolomics to Improve the Survival of Acute-On-Chronic Liver FailureScientists achieved a new progress in the functional metabolomics and translational medicine study of Acute-On-Chronic liver failure treatment. This work was published in the journal Advanced Science.Research group led by Prof. XU Guowang from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences, in collaboration with the research group from The First Affiliated Hospital of Zhengzhou University and National Institutes of Health, U.S.A. achieved a new progress in the functional metabolomics and translational medicine study of Acute-On-Chronic liver failure treatment. This work was published in the journal Advanced Science.

03 26, 2020Scientists Developed a New Treatment Method by Using Functional Metabolomics to Improve the Survival of Acute-On-Chronic Liver FailureScientists achieved a new progress in the functional metabolomics and translational medicine study of Acute-On-Chronic liver failure treatment. This work was published in the journal Advanced Science.Research group led by Prof. XU Guowang from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences, in collaboration with the research group from The First Affiliated Hospital of Zhengzhou University and National Institutes of Health, U.S.A. achieved a new progress in the functional metabolomics and translational medicine study of Acute-On-Chronic liver failure treatment. This work was published in the journal Advanced Science.

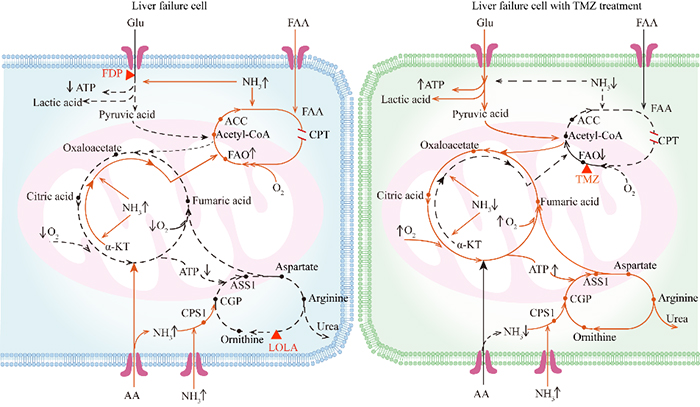

The schematic of the metabolic reprogramming of liver failure cell (left) and liver cell with TMZ treatment (right). (Image by ZHOU Yang) Acute-on-chronic liver failure (ACLF) is characterized by acute decompensation of liver function, organ failure(s), and high mortality. The main cause of ACLF in Asia is chronic HBV infection. Liver transplantation remains the only effective therapy, but a high mortality rate of patients on the waiting list is mainly caused by the rapid disease progression and the lack of donors. Thus, it is urgent to find an effective therapeutic strategy for patients with ACLF. In view of this problem, the metabolic reprogramming and intervention of liver failure were studied by using the strategy of functional metabolomics. By analyzing metabolic profiles in liver tissue samples from HBV-related ACLF patients and the controls, the metabolic characteristics of HBV-related ACLF patients were identified: inhibited glycolysis, tricarboxylic acid cycle and urea cycle, and enhanced fatty acid oxidation (FAO) and glutamine anaplerosis. These effects were mainly attributed to hyperammonemia and hypoxia. Further in vitro study revealed that switching from FAO to glycolysis could improve hepatocyte survival in the hyperammonemic and hypoxic microenvironment. Based on our insight into the mechanism of metabolic reprogramming in patients with ACLF, a novel treatment strategy was proposed for patients with ACLF: inhibiting FAO. Trimetazidine (TMZ) is a specific inhibitor of FAO that attenuates cardiomyocyte injury by switching the energy metabolism from FAO to glycolysis and has been used for anti-angina therapy. As expected, this study found that TMZ increased glycolysis, as evidenced by increased pyruvate levels and high extracellular acidification rate (ECAR) at maximal capacity, in the Chang liver cells exposed to hyperammonemia, which was accompanied by reduced ammonia levels. Intriguingly, it also increased the oxygen consumption rate (OCR) at both the basal level and maximal capacity and increased ATP generation, which suggested an enhanced oxidative phosphorylation Furthermore, TMZ effectively decreased the apoptosis rate in liver tissue from rats exposed to NH4Cl. A randomized clinical trial (ChiCTR-OPC-15006839) confirms that inhibiting FAO using TMZ improves the prognosis of patients with HBV-related ACLF, especially severe ACLF patients. In conclusion, this study provides a practical strategy for targeting metabolic reprogramming using TMZ to improve the survival of patients with HBV-related ACLF. This work was supported by the National Natural Science Foundation of China, National Key Research and Development Program of China. (Text by ZHOU Yang) -

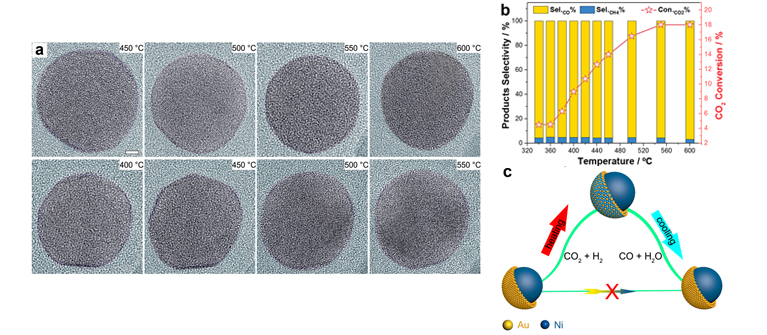

03 24, 2020Scientists reveal hidden catalytic surface of Ni-Au core-shell in CO2 hydrogenationScientists have found that the core-shell configuration of a Ni-Au catalyst was lost during the actual reaction and recovered afterwards. The Ni-Au alloy as the real active surface can solely be observed via in situ microscopy. The results were published in Nature Catalysis.For years, core-shell structured particles have been recognized as well-designed catalysts that can facilitate reaction activity owing to their distinct synergism at the interface. Recently, by using a combination of in situ methods, Dr. LIU Wei and his colleagues from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences have found that the core-shell configuration of a Ni-Au catalyst was lost during the actual reaction and recovered afterwards. The Ni-Au alloy as the real active surface can solely be observed via in situ microscopy. The results were published in Nature Catalysis. Supported metal nanoparticles can change their size, structure, and active surface composition under reaction conditions, thus functioning differently than expected.As for core-shell nanoparticles - one of the most popular heterogeneous catalysts - it is accepted that their catalytic properties derive from the synergy of electronics and geometry between the core and shell layer. However, lack of direct in situ evidence visualizing the localized atomic coordination/arrangement during real reactions impedes our understanding of actual structure-activity mechanism and core-shell functionality. Fig. 1a) In situ TEM image series; Fig. 1b) catalytic performance; Fig. 1c) schematic illustration The researchers from DICP described the real catalytic surface of a Ni-Au bimetallic catalyst. Without in situ characterization, it showed no difference from any other reported core-shell catalysis. Its high CO selectivity (>95%) (Fig. 1b) could be attributed to the well-controlled ultra-thin (about two atoms thick) Au shell, since a nickel catalyst always yields methane. However, by using environmental transmission electron microscopy to directly visualize the dynamic process at the atomic level (Fig. 1a), the researchers disclosed that the core-shell structure contributed nothing to the reactivity because the core-shell Ni-Au kinetically transformed into a Ni-Au alloy during the reaction and dramatically reverted to the core-shell configuration after the reaction (Fig. 1c). This discovery has been well supported by results from multiple in situ techniques, including synchrotron X-ray spectroscopy and infrared spectroscopy as well as theoretical simulations. This finding regarding core-shell nanoparticles overturns our conventional understanding. As a result, researchers may begin to question whether core-shell catalysts are really in core-shell structure under working conditions or not. The discovery of this hidden transformation also indicates that efforts to synthesize core-shell structures may be unnecessary in some reactions.(Text/Image by ZHANG Xiaoben, LIU Wei)

03 24, 2020Scientists reveal hidden catalytic surface of Ni-Au core-shell in CO2 hydrogenationScientists have found that the core-shell configuration of a Ni-Au catalyst was lost during the actual reaction and recovered afterwards. The Ni-Au alloy as the real active surface can solely be observed via in situ microscopy. The results were published in Nature Catalysis.For years, core-shell structured particles have been recognized as well-designed catalysts that can facilitate reaction activity owing to their distinct synergism at the interface. Recently, by using a combination of in situ methods, Dr. LIU Wei and his colleagues from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences have found that the core-shell configuration of a Ni-Au catalyst was lost during the actual reaction and recovered afterwards. The Ni-Au alloy as the real active surface can solely be observed via in situ microscopy. The results were published in Nature Catalysis. Supported metal nanoparticles can change their size, structure, and active surface composition under reaction conditions, thus functioning differently than expected.As for core-shell nanoparticles - one of the most popular heterogeneous catalysts - it is accepted that their catalytic properties derive from the synergy of electronics and geometry between the core and shell layer. However, lack of direct in situ evidence visualizing the localized atomic coordination/arrangement during real reactions impedes our understanding of actual structure-activity mechanism and core-shell functionality. Fig. 1a) In situ TEM image series; Fig. 1b) catalytic performance; Fig. 1c) schematic illustration The researchers from DICP described the real catalytic surface of a Ni-Au bimetallic catalyst. Without in situ characterization, it showed no difference from any other reported core-shell catalysis. Its high CO selectivity (>95%) (Fig. 1b) could be attributed to the well-controlled ultra-thin (about two atoms thick) Au shell, since a nickel catalyst always yields methane. However, by using environmental transmission electron microscopy to directly visualize the dynamic process at the atomic level (Fig. 1a), the researchers disclosed that the core-shell structure contributed nothing to the reactivity because the core-shell Ni-Au kinetically transformed into a Ni-Au alloy during the reaction and dramatically reverted to the core-shell configuration after the reaction (Fig. 1c). This discovery has been well supported by results from multiple in situ techniques, including synchrotron X-ray spectroscopy and infrared spectroscopy as well as theoretical simulations. This finding regarding core-shell nanoparticles overturns our conventional understanding. As a result, researchers may begin to question whether core-shell catalysts are really in core-shell structure under working conditions or not. The discovery of this hidden transformation also indicates that efforts to synthesize core-shell structures may be unnecessary in some reactions.(Text/Image by ZHANG Xiaoben, LIU Wei) -

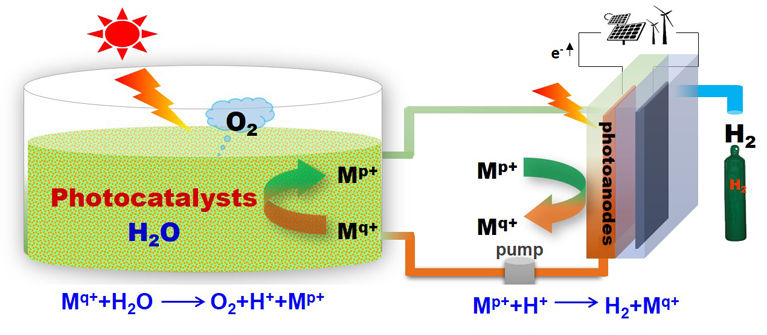

03 24, 2020Scientists proposed a practically feasible approach for scalable solar hydrogen production via water splittingScientists proposed and demonstrated a practically feasible approach for scalable solar hydrogen production via water splitting, named “Hydrogen Farm Project” (HFP), which enables achieving a world record solar-to-hydrogen efficiency exceeding 1.8% so far. This work was published on Angew. Chem. Int. Ed.Research groups led by Prof. LI Can and Prof. LI Rengui from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences proposed and demonstrated a practically feasible approach for scalable solar hydrogen production via water splitting, named “Hydrogen Farm Project” (HFP), which enables achieving a world record solar-to-hydrogen efficiency exceeding 1.8% so far. This work was published on Angew. Chem. Int. Ed. Harvesting and converting solar energy in the form of chemical fuels is one of appealing solutions for solar energy storage and utilization. Among the solutions for solar-to-chemical energy conversion, photocatalytic overall water splitting using particulate photocatalysts is regarded as an economical approach for large-scale hydrogen production owing to the merits of relatively low investment cost and technical simplicity. However, photocatalytic overall water splitting still suffers from extremely low solar-to-hydrogen conversion efficiency due to the poor charge separation efficiency and the possible reverse reaction between H2 and O2. Moreover, most of the reported visible-light-responsive particulate photocatalysts are only active for either hydrogen evolution or oxygen production half reaction in the presence of sacrificial reagents.Natural photosynthesis in green plants offers a textbook for efficient capturing of solar energy in a large scale, in which water oxidation reaction is initially realized in PSII, where molecular oxygen evolves while supplying protons for the following energy storage step via the synthesis of carbohydrates. Inspired by the natural photosynthesis, the researches in DICP proposed a practically feasible solar energy storage approach via a redox shuttle ion loop comprising with two sub-systems: one is highly efficient photocatalytic water oxidation for solar energy storage and protons production, and the other to utilize protons to produce H2. As such approach is principally analogue to the agricultural farm process, namely planting crops in a large scale and then concentrating to harvest once crops were ripe, so we named the approach as "Hydrogen Farm" Project (HFP). In the HFP, water oxidation and proton reduction reactions are spatially separated, consequently leaving out the H2/O2 gas separation. To fulfill the HFP approach, two difficulties must be overcome, one is highly active photocatalysts required for efficient photocatalytic water oxidation in the presence of shuttle ions, and another obstacle is suppressing the oxidation process of the reduced shuttle ions, named as the reverse reaction between shuttle ions. Based on the previous findings on spatial charge separation between different facets of semiconductors, the researchers in DICP experimentally demonstrated that BiVO4 crystals exposing both {010} and {110} facets exhibit an extremely high efficiency for water oxidation, resulting an AQE up to 71%, and more importantly, the reverse reaction of Fe2+ shuttle ions can be completely blocked. With this ideal photocatalyst, successful realization of the HFP approach was achieved. The scheme of hydrogen farm strategy for scalable solar hydrogen production via water splitting. (Image by LI Rengui, ZHAO Yue) An overall solar-to-chemical efficiency over 1.9% and a solar-to-hydrogen efficiency exceeding 1.8% could be achieved, which is the world record efficiency for photocatalytic water splitting systems so far. Meanwhile, a scalable photocatalyst panel for solar energy storage via HFP was well demonstrated under sunlight irradiation outdoors. This work offers a promising and practical strategy for solar energy harvesting and solar hydrogen production on a large scale by using particulate photocatalysts. The work was financially supported by National Natural Science Foundation of China, Strategic Priority Research Program of Chinese Academy of Science and Key Research Program of Frontier Sciences of Chinese Academy of Sciences. (Text by LI Rengui Li, ZHAO Yue)

03 24, 2020Scientists proposed a practically feasible approach for scalable solar hydrogen production via water splittingScientists proposed and demonstrated a practically feasible approach for scalable solar hydrogen production via water splitting, named “Hydrogen Farm Project” (HFP), which enables achieving a world record solar-to-hydrogen efficiency exceeding 1.8% so far. This work was published on Angew. Chem. Int. Ed.Research groups led by Prof. LI Can and Prof. LI Rengui from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences proposed and demonstrated a practically feasible approach for scalable solar hydrogen production via water splitting, named “Hydrogen Farm Project” (HFP), which enables achieving a world record solar-to-hydrogen efficiency exceeding 1.8% so far. This work was published on Angew. Chem. Int. Ed. Harvesting and converting solar energy in the form of chemical fuels is one of appealing solutions for solar energy storage and utilization. Among the solutions for solar-to-chemical energy conversion, photocatalytic overall water splitting using particulate photocatalysts is regarded as an economical approach for large-scale hydrogen production owing to the merits of relatively low investment cost and technical simplicity. However, photocatalytic overall water splitting still suffers from extremely low solar-to-hydrogen conversion efficiency due to the poor charge separation efficiency and the possible reverse reaction between H2 and O2. Moreover, most of the reported visible-light-responsive particulate photocatalysts are only active for either hydrogen evolution or oxygen production half reaction in the presence of sacrificial reagents.Natural photosynthesis in green plants offers a textbook for efficient capturing of solar energy in a large scale, in which water oxidation reaction is initially realized in PSII, where molecular oxygen evolves while supplying protons for the following energy storage step via the synthesis of carbohydrates. Inspired by the natural photosynthesis, the researches in DICP proposed a practically feasible solar energy storage approach via a redox shuttle ion loop comprising with two sub-systems: one is highly efficient photocatalytic water oxidation for solar energy storage and protons production, and the other to utilize protons to produce H2. As such approach is principally analogue to the agricultural farm process, namely planting crops in a large scale and then concentrating to harvest once crops were ripe, so we named the approach as "Hydrogen Farm" Project (HFP). In the HFP, water oxidation and proton reduction reactions are spatially separated, consequently leaving out the H2/O2 gas separation. To fulfill the HFP approach, two difficulties must be overcome, one is highly active photocatalysts required for efficient photocatalytic water oxidation in the presence of shuttle ions, and another obstacle is suppressing the oxidation process of the reduced shuttle ions, named as the reverse reaction between shuttle ions. Based on the previous findings on spatial charge separation between different facets of semiconductors, the researchers in DICP experimentally demonstrated that BiVO4 crystals exposing both {010} and {110} facets exhibit an extremely high efficiency for water oxidation, resulting an AQE up to 71%, and more importantly, the reverse reaction of Fe2+ shuttle ions can be completely blocked. With this ideal photocatalyst, successful realization of the HFP approach was achieved. The scheme of hydrogen farm strategy for scalable solar hydrogen production via water splitting. (Image by LI Rengui, ZHAO Yue) An overall solar-to-chemical efficiency over 1.9% and a solar-to-hydrogen efficiency exceeding 1.8% could be achieved, which is the world record efficiency for photocatalytic water splitting systems so far. Meanwhile, a scalable photocatalyst panel for solar energy storage via HFP was well demonstrated under sunlight irradiation outdoors. This work offers a promising and practical strategy for solar energy harvesting and solar hydrogen production on a large scale by using particulate photocatalysts. The work was financially supported by National Natural Science Foundation of China, Strategic Priority Research Program of Chinese Academy of Science and Key Research Program of Frontier Sciences of Chinese Academy of Sciences. (Text by LI Rengui Li, ZHAO Yue) -

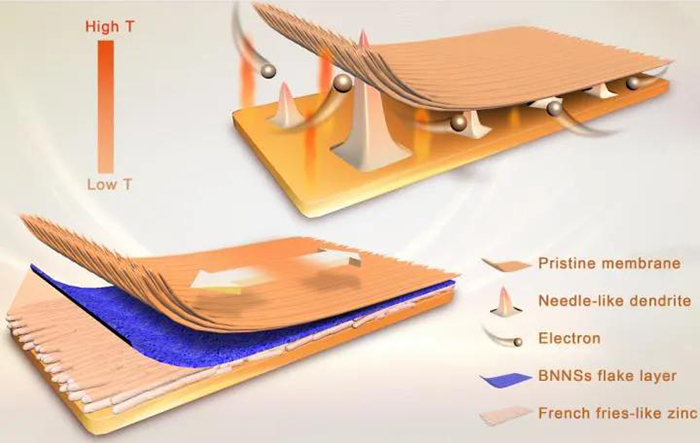

03 17, 2020A Boron Nitride Nanosheets Composite Membrane for a Long‐Life Zinc‐Based Flow BatteryScientists recently developed a composite membrane for long-life zinc-based flow batteries. Their study was published in Angewandte Chemie International Edition.Researchers led by Profs. LI Xianfeng from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences recently developed a composite membrane for long-life zinc-based flow batteries. Their study was published in Angewandte Chemie International Edition. The zinc-based flow battery (ZFB) has captured much attention as a stationary energy storage application due to its low cost, intrinsic high safety and environmental friendliness. However, its development is limited by poor cycle life and poor charge-discharge performance, mainly due to zinc dendrite/accumulation issues. Ion-conducting membranes play an important role in regulating the morphology of zinc deposition and inhibiting the growth of dendrites, thereby improving the cycling stability of the battery. In the early stage of their research, LI's group adjusted the direction and morphology of zinc deposition by modulating the negative charge properties of the porous ion-conducting membrane, thus improving the area capacity and cycling stability of zinc-based flow batteries (Nat. Commun., 2018). Based on their previous work, the researchers then developed a composite membrane by coating boron nitride nanosheets (BNNSs) exhibiting high thermal conductivity and mechanical strength onto a porous membrane substrate. Schematic illustration of the synergistic effect (thermal conductivity and mechanical strength) of BNNSs flake layer on zinc deposition. The BNNSs flake layer facing the negative electrode serves as the heat-porter, thus improving the surface temperature distribution of the electrode and further adjusting the zinc morphology. Moreover, its high level of mechanical strength prevents the metallic zinc from damaging the membrane. The synergistic effect of these two factors can improve the cycle life of ZFBs. Alkaline zinc-iron flow batteries assembled with this membrane can stably run for 500 charge-discharge cycles (~800 h) at a current density of 80 mA cm-2 without significant attenuation. Most importantly, energy efficiency above 80% can be obtained even at 200 mA cm-2. These results may serve as a reference for the regulation of zinc anodes in zinc-based batteries.

03 17, 2020A Boron Nitride Nanosheets Composite Membrane for a Long‐Life Zinc‐Based Flow BatteryScientists recently developed a composite membrane for long-life zinc-based flow batteries. Their study was published in Angewandte Chemie International Edition.Researchers led by Profs. LI Xianfeng from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences recently developed a composite membrane for long-life zinc-based flow batteries. Their study was published in Angewandte Chemie International Edition. The zinc-based flow battery (ZFB) has captured much attention as a stationary energy storage application due to its low cost, intrinsic high safety and environmental friendliness. However, its development is limited by poor cycle life and poor charge-discharge performance, mainly due to zinc dendrite/accumulation issues. Ion-conducting membranes play an important role in regulating the morphology of zinc deposition and inhibiting the growth of dendrites, thereby improving the cycling stability of the battery. In the early stage of their research, LI's group adjusted the direction and morphology of zinc deposition by modulating the negative charge properties of the porous ion-conducting membrane, thus improving the area capacity and cycling stability of zinc-based flow batteries (Nat. Commun., 2018). Based on their previous work, the researchers then developed a composite membrane by coating boron nitride nanosheets (BNNSs) exhibiting high thermal conductivity and mechanical strength onto a porous membrane substrate. Schematic illustration of the synergistic effect (thermal conductivity and mechanical strength) of BNNSs flake layer on zinc deposition. The BNNSs flake layer facing the negative electrode serves as the heat-porter, thus improving the surface temperature distribution of the electrode and further adjusting the zinc morphology. Moreover, its high level of mechanical strength prevents the metallic zinc from damaging the membrane. The synergistic effect of these two factors can improve the cycle life of ZFBs. Alkaline zinc-iron flow batteries assembled with this membrane can stably run for 500 charge-discharge cycles (~800 h) at a current density of 80 mA cm-2 without significant attenuation. Most importantly, energy efficiency above 80% can be obtained even at 200 mA cm-2. These results may serve as a reference for the regulation of zinc anodes in zinc-based batteries. -

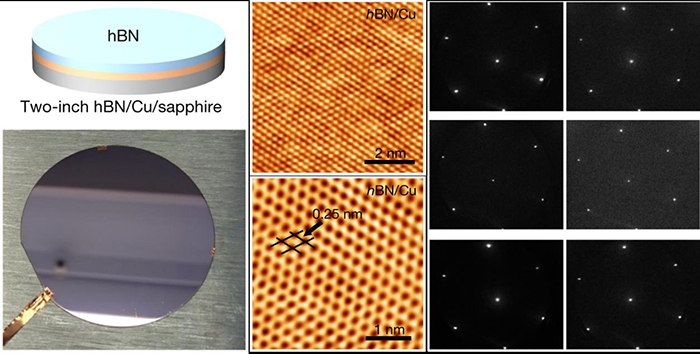

03 16, 2020A New Progress in Wafer-scale Single-crystal Hexagonal Boron Nitride Monolayers Identified by DUV-PEEM/LEEMScientists reported the successful epitaxial growth of single-crystal hexagonal boron nitride (hBN) monolayers on a Cu (111) thin film across a two-inch c-plane sapphire wafer. The results were published in Nature.A research team led by Prof. FU Qiang from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences, in collaboration with Prof. LI Lain-Jong from Taiwan Semiconductor Manufacturing Company (TSMC), Prof. CHANG Wen-Hao from National Chiao Tung University, Prof. Boris I. YAKOBSON from Rice University and Prof. ZHANG Yanfeng from Peking University reported the successful epitaxial growth of single-crystal hexagonal boron nitride (hBN) monolayers on a Cu (111) thin film across a two-inch c-plane sapphire wafer. The results were published in Nature. Ultrathin hexagonal boron nitride is expected to be one of the best candidate materials for future 2D electronics. However, reliable production of wafer-scale single-crystal hBN films which are compatible with advanced microelectronics fabrication processes still remains a challenge. The joint research teams first deposited 500 nm thick single-crystal Cu(111) thin films without any twinned grains on c-plane sapphire wafers. Single-crystal hBN monolayers were epitaxially grown on the inch-sized substrates. Scientists in DICP used a deep ultraviolet laser photoemission electron microscopy and low-energy electron microscopy (DUV-PEEM/LEEM) system developed by the State Key Lab of Catalysis to characterize the single crystalline quality within the large-area monolayer film.

03 16, 2020A New Progress in Wafer-scale Single-crystal Hexagonal Boron Nitride Monolayers Identified by DUV-PEEM/LEEMScientists reported the successful epitaxial growth of single-crystal hexagonal boron nitride (hBN) monolayers on a Cu (111) thin film across a two-inch c-plane sapphire wafer. The results were published in Nature.A research team led by Prof. FU Qiang from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences, in collaboration with Prof. LI Lain-Jong from Taiwan Semiconductor Manufacturing Company (TSMC), Prof. CHANG Wen-Hao from National Chiao Tung University, Prof. Boris I. YAKOBSON from Rice University and Prof. ZHANG Yanfeng from Peking University reported the successful epitaxial growth of single-crystal hexagonal boron nitride (hBN) monolayers on a Cu (111) thin film across a two-inch c-plane sapphire wafer. The results were published in Nature. Ultrathin hexagonal boron nitride is expected to be one of the best candidate materials for future 2D electronics. However, reliable production of wafer-scale single-crystal hBN films which are compatible with advanced microelectronics fabrication processes still remains a challenge. The joint research teams first deposited 500 nm thick single-crystal Cu(111) thin films without any twinned grains on c-plane sapphire wafers. Single-crystal hBN monolayers were epitaxially grown on the inch-sized substrates. Scientists in DICP used a deep ultraviolet laser photoemission electron microscopy and low-energy electron microscopy (DUV-PEEM/LEEM) system developed by the State Key Lab of Catalysis to characterize the single crystalline quality within the large-area monolayer film.

Wafer-scale single-crystal hexagonal boron nitride monolayers identified by STM and micro-region LEED. (Image by LI Rongtan)

By making use of the unique micro-region surface imaging and surface diffraction capability of the setup, the whole hBN monolayer has been revealed to be unidirectionally aligned with the Cu (111) surfaces by probing around one hundred micrometer-sized spots across the one-inch hBN wafer confirming the single-crystallinity of the hBN monolayer films. This work was financially supported by the National Natural Science Foundation of China, the Strategic Priority Research Program (B) of the Chinese Academy of Sciences, and National Key Scientific Instrument and Equipment Development Project. (Text by LI Rongtan) -

03 13, 2020DICP Scientists Developed High Energy Density All Solid-State Sodium Batteries with Excellent FlexibilityScientists recently developed high energy density all solid-state sodium ion batteries with excellent flexibility by building an integrated system of solvent free solid polymer electrolyte and cathode material. The batteriescan effectively strengthen the solid-solid interface contract, reduce the interface impedance, and significantly improve the transfer efficiency of electrons, ions and charges. Their results were published on Advanced Energy Materials. ?Researchers led by Prof. WU Zhong-Shuai from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. YU Yan from University of Science and Technology of China and Prof. Yao Yinxia from Ningbo Institute of Materials Technology & Engineering of CAS, recently developed high energy density all solid-state sodium ion batteries with excellent flexibility by building an integrated system of solvent free solid polymer electrolyte and cathode material. The batteriescan effectively strengthen the solid-solid interface contract, reduce the interface impedance, and significantly improve the transfer efficiency of electrons, ions and charges. Their results were published on Advanced Energy Materials.

03 13, 2020DICP Scientists Developed High Energy Density All Solid-State Sodium Batteries with Excellent FlexibilityScientists recently developed high energy density all solid-state sodium ion batteries with excellent flexibility by building an integrated system of solvent free solid polymer electrolyte and cathode material. The batteriescan effectively strengthen the solid-solid interface contract, reduce the interface impedance, and significantly improve the transfer efficiency of electrons, ions and charges. Their results were published on Advanced Energy Materials. ?Researchers led by Prof. WU Zhong-Shuai from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. YU Yan from University of Science and Technology of China and Prof. Yao Yinxia from Ningbo Institute of Materials Technology & Engineering of CAS, recently developed high energy density all solid-state sodium ion batteries with excellent flexibility by building an integrated system of solvent free solid polymer electrolyte and cathode material. The batteriescan effectively strengthen the solid-solid interface contract, reduce the interface impedance, and significantly improve the transfer efficiency of electrons, ions and charges. Their results were published on Advanced Energy Materials.

Schematic diagram of flexible all solid-state sodium ion batteries and the corresponding cycling stability. (Image by HOU Xiaocheng)

Sodium ion batteries are considered as ideal devices for large-scale energy storage due to its abundant sodium resources and low cost. Traditional sodium ion batteries mostly used liquid organic electrolytes, which are prone to leakage and combustion. Using solid sodium ion electrolytes instead of flammable organic liquid electrolytes can greatly improve battery safety. However, the development of all solid-state sodium ion batteries are facing the great challenges: (1) the low ionic conductivity of the solid-state electrolyte; (2) the poor interface compatibility between the solid-state electrolyte and the electrode materials; and (3) the large volume change of the electrode materials during the intercalation and de-intercalation of sodium ions. All of these problems lead to the large internal resistance, low capacity and short lifespan of the solid sodium batteries. Therefore, it is urgently needed to develop more efficient solutions to overcome these issues and satisfy the needs of commercial applications. The scientists developed a novel solid-state polymer electrolyte (PEGDMA-NaFSI-SPE) by utilizing in situ solvent-free UV-cured method firstly, which has a high ionic conductivity (up to 10-4 S/cm at the room temperature) and excellent flexibility. Then sodium vanadium phosphate modified by a thin layer of carbon (5 nm) cathode materials (Na3V2(PO4)3, NVP@C) with improved electron, ion and charge transfer efficiency were synthesized by sol-gel method. Based on the previous work, scientists built an polymer electrolyte/electrode material integrated system for high-performance all solid-state sodium battery (NVP@C?PEGDMA-NaFSI-SPE?Na) using carbon coated NVP@C composite nanosheets as the cathode, solvent free solid polymer PEGDMA-NaFSI-SPE as the electrolyte and metallic sodium as the anode, which effectively strengthened the solid-solid interface contact, reduced the battery interface impedance, and realized a flexible solid-state sodium battery with high specific energy and long life. The battery can be stably cycled 740 times at a rate of 0.5 C, and the capacity decay rate is only 0.007% for each time. Meanwhile, the capacity retention rate was still as high as 95% even after 3 months resting, indicative of low self-discharge rate of the all solid-state sodium battery. What is more, the soft-packed sodium battery can still provide an energy density of up to 355 Wh/kg after 535 cycles under the flat and bent states. The design strategy of this work provides a new direction for the development and application of flexible and high energy density all solid-state sodium batteries.

This work was supported by such as National Natural Science Foundation of China, National Key R&D Program of China, Dalian National Laboratory for Clean Energy of CAS. (Text by HOU Xiaocheng)