Research News

-

05 18, 2017DICP Ion Mobility Spectrometer Participated in 2017 Chengdu Global Innovation and Entrepreneurship Fair

05 18, 2017DICP Ion Mobility Spectrometer Participated in 2017 Chengdu Global Innovation and Entrepreneurship Fair

The 2017 Chengdu Global Innovation and Entrepreneurship Fair (CGIEF) for artificial intelligence, black technology and other world's cutting edge products and innovative technology, is open in Chengdu Century Metro International Convention and Exhibition Center on May 10, 2017. Entrepreneurial teams,guests and visitors from 47 countries and region, including four Nobel Prize winners, 14 academicians and 58 heads of world-renowned universities attend and visit the exhibition during three day. The portable chemicals on-site detection mass spectrometer and non-radioactive ion source ion mobility spectrometer (IMS) set up by the Laboratory for Rapid Separation and Detection of DICP, CAS, are exhibited in this CGIEF.

With the socio-economic development, more and more illegal drugs (such as: stimulants, drugs, fake and shoddy drugs, etc.) appear in people's lives, the use of these illicit drugs not only endanger personal health, but also threaten the community stability and economic development. Portable ion trap mass spectrometer based on miniaturization of mass spectrometry technology to promote the on-site qualitative and quantitative analysis of illegal drugs, providing a powerful weapon for illegal drugs on-site inspection and evidence. The instrument uses a variety of innovative technologies (such as thermal desorption sample introduction technology, reagent-assisted VUV soft ionization technology, non-continuous atmospheric pressure interface technology and tandem mass spectrometry technology), to ensure the accuracy of detection while achieving the instrument portable Integrated (volume of 35 * 32 * 30 cm3, weight of 16.2 kg). At present, the instrument has passed the "China New Era Certification Center" GB/T1900-2008/ISO9001:2008 quality management certification, and the Portable ion trap mass spectrometer was used for on-site demonstration applications in De Hong County, Mu Kang checkpoint, Yu Xi City Public Security Bureau, Qing Long Chang checkpoint and other places of Yunnan Province, the it also was selected to participate "the second military and civilian integration exhibition" held in Beijing in 2016.

The non-radioactive ion source ion mobility spectrometry technology for 0n-site rapid detection of explosives, drugs and drug analysis, is closely tracking the security requirements for various dangerous substances detection. The portable single-tube dual-mode and dual-tube dual-mode ion mobility spectrometry can detect, analysis, identification of explosives, illegal drugs and medical drugs, including the common black powder explosives and the international new type of peroxide explosives, with high sensitivity and specificity. Based on patents and our own intellectual properties, a variety of products have successfully passed the certification of China Certification Center for Security and Protection. The IMS products have been used in Tianjin, Xi'an, Lanzhou, Beijing, Nanjing and other places, contributing to maintain social security and stability, and participate in the handling of emergencies.

On the first day of the exhibition, the portable ion trap mass spectrometer and the portable explosives drug detector were introduecd to Li Yin, the deputy secretary of provincial committee and governor of Sichuan province and other leaders. They watched the demonstration of the instrument, and fully affirmed the contribution made by the on-site rapid detection equipment in the field of national social security. During the three-day fair, a number of domestic enterprises consulted with the delegates of group 102 on the on-site detection of illegal drugs, soil explosives and new peroxide explosives, exchange and learning, and reached some preliminary cooperation intentions for the relevant technology transfer. (By LI Jinghua and WANG Shuang) -

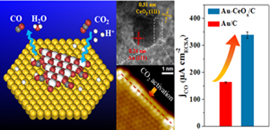

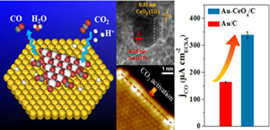

05 11, 2017Scientists Enhance CO2 Electroreduction with Metal-Oxide InterfaceProf. BAO Xinhe's research team in the State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, has recently made research progress in metal-oxide interface enhanced CO2 electroreduction.

05 11, 2017Scientists Enhance CO2 Electroreduction with Metal-Oxide InterfaceProf. BAO Xinhe's research team in the State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, has recently made research progress in metal-oxide interface enhanced CO2 electroreduction.

The electrochemical CO2 reduction reaction (CO2RR) is powered by renewable electricity or surplus nuclear electricity. It can be used to prepare carbon monoxide, formic acid, hydrocarbon, alcohol, other high value fuel and chemicals in one step under relatively mild reaction conditions. The process can simultaneously achieve efficient CO2 conversion and clean energy storage. At present, designing efficient catalysts to decrease the overpotential and enhance reaction selectivity is the challenging research focus for CO2RR.

Prof. BAO Xinhe's research team in the State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, has recently made research progress in metal-oxide interface enhanced CO2 electroreduction.

Based on the previous CO2RR studies and the understanding of the metal-oxide interfacial confinement catalysis, they design and prepare carbon supported Au-CeOx catalyst with metal-oxide interface structure. They also investigate the relationship between the Au-CeOx interface and catalytic performance of CO2RR. The CO Faradaic Efficiency reaches 89.1% over Au-CeOx/C at -0.89 V vs. reversible hydrogen electrode (RHE). The result is significantly higher than 59.0% and 9.8% over Au/C and CeOx/C at the same potential. The CO geometric current density over Au-CeOx/C (12.9 mA cm-2) is about 1.6 times of that over Au/C (8.3 mA cm-2) at -0.89 V vs. RHE. In situ scanning tunnelling microscopy and synchrotron-radiation photoemission spectroscopy show that the Au-CeOx interface is dominant in enhancing CO2 adsorption and activation. It can be further promoted by the presence of hydroxyl groups. Density functional theory calculations indicate that the Au-CeOx interface is the active site for CO2 activation and the reduction to CO. The synergy between Au and CeOx promotes the stability of key carboxyl intermediate (*COOH), thus facilitates CO2RR. Similar interface-enhanced CO2RR is further observed on Ag-CeOx, demonstrating the generality of the strategy for enhancing CO2RR. The research results may provide a new way to regulate the CO2RR performance, and enrich and expand the concept of nano-confined catalysis proposed by the research team.

Enhancing CO2 Electroreduction with the Metal-Oxide Interface(Image by GAO Dunfeng, ZHANG Yi and ZHOU Zhiwen)

The results are published in Journal of the American Chemical Society (J. Am. Chem. Soc. 2017, 139, 5652). This work was financially supported by Natural Science Foundation of China, National Key R&D Program of China and Strategic Priority Research Program of the Chinese Academy of Sciences. (Text and Image by GAO Dunfeng, ZHANG Yi and ZHOU Zhiwen)

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn -

05 11, 2017Scientists Enhance CO2 Electroreduction with Metal-Oxide InterfaceProf. BAO Xinhe's research team in the State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, has recently made research progress in metal-oxide interface enhanced CO2 electroreduction.

05 11, 2017Scientists Enhance CO2 Electroreduction with Metal-Oxide InterfaceProf. BAO Xinhe's research team in the State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, has recently made research progress in metal-oxide interface enhanced CO2 electroreduction.

The electrochemical CO2 reduction reaction (CO2RR) is powered by renewable electricity or surplus nuclear electricity. It can be used to prepare carbon monoxide, formic acid, hydrocarbon, alcohol, other high value fuel and chemicals in one step under relatively mild reaction conditions. The process can simultaneously achieve efficient CO2 conversion and clean energy storage. At present, designing efficient catalysts to decrease the overpotential and enhance reaction selectivity is the challenging research focus for CO2RR.

Prof. BAO Xinhe's research team in the State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, has recently made research progress in metal-oxide interface enhanced CO2 electroreduction.

Based on the previous CO2RR studies and the understanding of the metal-oxide interfacial confinement catalysis, they design and prepare carbon supported Au-CeOx catalyst with metal-oxide interface structure. They also investigate the relationship between the Au-CeOx interface and catalytic performance of CO2RR. The CO Faradaic Efficiency reaches 89.1% over Au-CeOx/C at -0.89 V vs. reversible hydrogen electrode (RHE). The result is significantly higher than 59.0% and 9.8% over Au/C and CeOx/C at the same potential. The CO geometric current density over Au-CeOx/C (12.9 mA cm-2) is about 1.6 times of that over Au/C (8.3 mA cm-2) at -0.89 V vs. RHE. In situ scanning tunnelling microscopy and synchrotron-radiation photoemission spectroscopy show that the Au-CeOx interface is dominant in enhancing CO2 adsorption and activation. It can be further promoted by the presence of hydroxyl groups. Density functional theory calculations indicate that the Au-CeOx interface is the active site for CO2 activation and the reduction to CO. The synergy between Au and CeOx promotes the stability of key carboxyl intermediate (*COOH), thus facilitates CO2RR. Similar interface-enhanced CO2RR is further observed on Ag-CeOx, demonstrating the generality of the strategy for enhancing CO2RR. The research results may provide a new way to regulate the CO2RR performance, and enrich and expand the concept of nano-confined catalysis proposed by the research team.

Enhancing CO2 Electroreduction with the Metal-Oxide Interface(Image by GAO Dunfeng, ZHANG Yi and ZHOU Zhiwen)

The results are published in Journal of the American Chemical Society (J. Am. Chem. Soc. 2017, 139, 5652). This work was financially supported by Natural Science Foundation of China, National Key R&D Program of China and Strategic Priority Research Program of the Chinese Academy of Sciences. (Text and Image by GAO Dunfeng, ZHANG Yi and ZHOU Zhiwen)

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn -

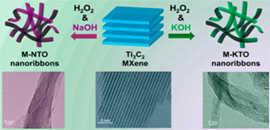

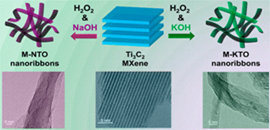

05 09, 2017Scientists Develop MXene-Derived Titanate Nanoribbons for High-Performance Sodium and Potassium Ion Batteriesscientists WU Zhongshuai and BAO Xinhe et al at Dalian Institute of Chemical Physics, collaborated with WANG Xiaohui from Institute of Metal Research, developed ultrathin nanoribbons of sodium titanate (M-NTO) and potassium titanate (MKTO) for high-performance SIBs and PIBs.

05 09, 2017Scientists Develop MXene-Derived Titanate Nanoribbons for High-Performance Sodium and Potassium Ion Batteriesscientists WU Zhongshuai and BAO Xinhe et al at Dalian Institute of Chemical Physics, collaborated with WANG Xiaohui from Institute of Metal Research, developed ultrathin nanoribbons of sodium titanate (M-NTO) and potassium titanate (MKTO) for high-performance SIBs and PIBs.

Sodium ion batteries (SIBs) and potassium ion batteries (PIBs) are promising as ideal alternatives to Lithium ion batteries (LIBs), because of their rich abundance (Na, K), low cost, high theoretical capacities, and similar redox potentials. However, it usually lead to low capacities and/or fast capacity fading, due to the huge volume expansion and sluggish kinetics in most electrodes (e.g., metal oxide, porous carbon) induced by large Na+ or K+ ions. Therefore, urgent development of nanostructural electrode materials with enhanced charge storage mechanism is highly required to meet the coming era of next-generation batteries (SIBs, PIBs).

Ti-based layered materials, such as sodium/potassium titanate and Ti-based MXene (two dimensional transit carbide (nitride), e.g., Ti3C2, Ti2C), have been intensively explored in SIBs and PIBs. They exhibited suitable interlayer spacing for accommodating Na+/K+ ions, low working potentials, exceptional chemical durability, and environmental benignity. Notably, electrochemical performances of these materials are strongly dependent on their nanostructures.

Two-dimensional (2D) MXene nanosheets (e.g., Ti3C2) have gained enormous attention, because of their high conductivity, flexible interlayer space, tailored surface chemistry and promising applications in LIBs, SIBs, and PIBs. The hydrofluoric acid etched multilayer MXene nanosheets are terminated by oxygen and fluorine-containing groups. It usually shows severe structural defects, leading to large initial irreversible capacities and limited reversible capacities. Therefore, it is of great significance for improving sodium and potassium storage kinetics of SIBs and PIBs, by designing well-defined layered Ti-based nanostructures with suitable interlayer spacing and stable structure.

Ti3C2 MXene derived sodium/potassium titanate nanoribbons synthesized by a simultaneous oxidation and alkalization process (Image by DONG Yanfeng and ZHAO Xuejun)

To address this, scientists WU Zhongshuai and BAO Xinhe et al at Dalian Institute of Chemical Physics, collaborated with WANG Xiaohui from Institute of Metal Research, developed ultrathin nanoribbons of sodium titanate (M-NTO) and potassium titanate (MKTO) for high-performance SIBs and PIBs.

M-NTO and M-KTO were successfully synthesized by a simultaneous oxidation and alkalization process of Ti3C2 MXene. M-NTO has the suitable interlayer spacing (0.90 nm for M-NTO, 0.93 nm for M-KTO), ultrathin thickness (<11 nm), narrow widths of nanoribbons (<60 nm), and open macroporous structures for enhanced ion insertion/extraction kinetics. As a result, it exhibited a large reversible capacity of 191 mAh g-1 at 200 mA g-1 for sodium storage, higher than those of pristine Ti3C2 (178 mAh g-1) and commercial TiC derivatives (86 mAh g-1).

Notably, M-KTO displayed long-term stable cyclability over 900 times, which outperforms other Ti-based layered materials reported to date. Moreover, this strategy can be extended for preparing a large number of MXene-derived materials, from the 60+ group of MAX phases, for various applications. This work has been published online in ACS Nano (DOI: 10.1021/acsnano.7b01165). (Text and Image by DONG Yanfeng and ZHAO Xuejun)

Funder: National Natural Science Foundation of China, Ministry of Science and Technology of China, Natural Science Foundation of Liaoning Province, DICP and China Postdoctoral Science Foundation.

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn

-

05 09, 2017Scientists Develop MXene-Derived Titanate Nanoribbons for High-Performance Sodium and Potassium Ion Batteriesscientists WU Zhongshuai and BAO Xinhe et al at Dalian Institute of Chemical Physics, collaborated with WANG Xiaohui from Institute of Metal Research, developed ultrathin nanoribbons of sodium titanate (M-NTO) and potassium titanate (MKTO) for high-performance SIBs and PIBs.

05 09, 2017Scientists Develop MXene-Derived Titanate Nanoribbons for High-Performance Sodium and Potassium Ion Batteriesscientists WU Zhongshuai and BAO Xinhe et al at Dalian Institute of Chemical Physics, collaborated with WANG Xiaohui from Institute of Metal Research, developed ultrathin nanoribbons of sodium titanate (M-NTO) and potassium titanate (MKTO) for high-performance SIBs and PIBs.

Sodium ion batteries (SIBs) and potassium ion batteries (PIBs) are promising as ideal alternatives to Lithium ion batteries (LIBs), because of their rich abundance (Na, K), low cost, high theoretical capacities, and similar redox potentials. However, it usually lead to low capacities and/or fast capacity fading, due to the huge volume expansion and sluggish kinetics in most electrodes (e.g., metal oxide, porous carbon) induced by large Na+ or K+ ions. Therefore, urgent development of nanostructural electrode materials with enhanced charge storage mechanism is highly required to meet the coming era of next-generation batteries (SIBs, PIBs).

Ti-based layered materials, such as sodium/potassium titanate and Ti-based MXene (two dimensional transit carbide (nitride), e.g., Ti3C2, Ti2C), have been intensively explored in SIBs and PIBs. They exhibited suitable interlayer spacing for accommodating Na+/K+ ions, low working potentials, exceptional chemical durability, and environmental benignity. Notably, electrochemical performances of these materials are strongly dependent on their nanostructures.

Two-dimensional (2D) MXene nanosheets (e.g., Ti3C2) have gained enormous attention, because of their high conductivity, flexible interlayer space, tailored surface chemistry and promising applications in LIBs, SIBs, and PIBs. The hydrofluoric acid etched multilayer MXene nanosheets are terminated by oxygen and fluorine-containing groups. It usually shows severe structural defects, leading to large initial irreversible capacities and limited reversible capacities. Therefore, it is of great significance for improving sodium and potassium storage kinetics of SIBs and PIBs, by designing well-defined layered Ti-based nanostructures with suitable interlayer spacing and stable structure.

Ti3C2 MXene derived sodium/potassium titanate nanoribbons synthesized by a simultaneous oxidation and alkalization process (Image by DONG Yanfeng and ZHAO Xuejun)

To address this, scientists WU Zhongshuai and BAO Xinhe et al at Dalian Institute of Chemical Physics, collaborated with WANG Xiaohui from Institute of Metal Research, developed ultrathin nanoribbons of sodium titanate (M-NTO) and potassium titanate (MKTO) for high-performance SIBs and PIBs.

M-NTO and M-KTO were successfully synthesized by a simultaneous oxidation and alkalization process of Ti3C2 MXene. M-NTO has the suitable interlayer spacing (0.90 nm for M-NTO, 0.93 nm for M-KTO), ultrathin thickness (<11 nm), narrow widths of nanoribbons (<60 nm), and open macroporous structures for enhanced ion insertion/extraction kinetics. As a result, it exhibited a large reversible capacity of 191 mAh g-1 at 200 mA g-1 for sodium storage, higher than those of pristine Ti3C2 (178 mAh g-1) and commercial TiC derivatives (86 mAh g-1).

Notably, M-KTO displayed long-term stable cyclability over 900 times, which outperforms other Ti-based layered materials reported to date. Moreover, this strategy can be extended for preparing a large number of MXene-derived materials, from the 60+ group of MAX phases, for various applications. This work has been published online in ACS Nano (DOI: 10.1021/acsnano.7b01165). (Text and Image by DONG Yanfeng and ZHAO Xuejun)

Funder: National Natural Science Foundation of China, Ministry of Science and Technology of China, Natural Science Foundation of Liaoning Province, DICP and China Postdoctoral Science Foundation.

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn

-

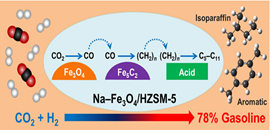

05 05, 2017DICP Researchers Develop an Efficient Multifunctional Catalyst for CO2 Hydrogenation to GasolineThe research team led by Dr. SUN Jian and Prof. GE Qingjie in Dalian Institute of Chemical Physics, has succeeded in preparing a high efficient, stable, and multifunctional Na–Fe3O4/HZSM-5 catalyst for the direct production of gasoline from CO2 hydrogenation. This catalyst exhibited 78% selectivity to C5–C11 as well as low CH4 and CO selectivity under industrial relevant conditions. And gasoline fraction are mainly isoparaffins and aromatics thus favouring the octane number. Moreover, the multifunctional catalyst exhibited a remarkable stability for 1,000 h on stream, which definitely has the potential to be a promising industrial catalyst for CO2 utilization to liquid fuels.

05 05, 2017DICP Researchers Develop an Efficient Multifunctional Catalyst for CO2 Hydrogenation to GasolineThe research team led by Dr. SUN Jian and Prof. GE Qingjie in Dalian Institute of Chemical Physics, has succeeded in preparing a high efficient, stable, and multifunctional Na–Fe3O4/HZSM-5 catalyst for the direct production of gasoline from CO2 hydrogenation. This catalyst exhibited 78% selectivity to C5–C11 as well as low CH4 and CO selectivity under industrial relevant conditions. And gasoline fraction are mainly isoparaffins and aromatics thus favouring the octane number. Moreover, the multifunctional catalyst exhibited a remarkable stability for 1,000 h on stream, which definitely has the potential to be a promising industrial catalyst for CO2 utilization to liquid fuels.

Converting CO2 from a detrimental greenhouse gas into value-added liquid fuels not only contributes to mitigating CO2 emissions, but also reduces dependence on petrochemicals. However, since CO2 is a fully oxidized, thermodynamically stable and chemically inert molecule, the activation of CO2 and its hydrogenation to hydrocarbons or other alcohols are challenging tasks. Most research to date, not surprisingly, is focusing on selective hydrogenation of CO2 to short-chain products, while few studies on long-chain hydrocarbons, such as gasoline-range (C5–C11) hydrocarbons. The key to this process is to search for a high efficient catalyst.

CO2 Hydrogenation to Gasoline-range Hydrocarbons Over Na–Fe3O4/Zeolite Multifunctional Catalyst

The research team led by Dr. SUN Jian and Prof. GE Qingjie in Dalian Institute of Chemical Physics, has succeeded in preparing a high efficient, stable, and multifunctional Na–Fe3O4/HZSM-5 catalyst for the direct production of gasoline from CO2 hydrogenation. This catalyst exhibited 78% selectivity to C5–C11 as well as low CH4 and CO selectivity under industrial relevant conditions. And gasoline fraction are mainly isoparaffins and aromatics thus favouring the octane number. Moreover, the multifunctional catalyst exhibited a remarkable stability for 1,000 h on stream, which definitely has the potential to be a promising industrial catalyst for CO2 utilization to liquid fuels.

In-depth characterizations indicate that this catalyst enables RWGS over Fe3O4 sites, olefin synthesis over Fe5C2 sites and oligomerization/aromatization/isomerization over zeolite acid sites. The concerted action of the active sites calls for precise control of their structures and proximity. This study paves a new path for the synthesis of liquid fuels by utilizing CO2 and H2. Furthermore, it provides an important approach for dealing with the intermittency of renewable sources (sun, wind and so on) by storing energy in liquid fuels.

This work was recently published on Nature Communications (DOI: 10.1038/ncomms15174). This work was financially supported by the National Natural Science Foundation of China, and the Hundred-Talent Program of DICP, Chinese Academy of Sciences. (Text and Image by WEI Jian)

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn

Embargo

1000 London time (BST) / 0500 US Eastern Daylight Time

1800 Japanese time / 1900 Australian Eastern Time