Energy-efficient membrane technologies are essential for reducing energy consumption and carbon emissions in industrial separations. Two-dimensional metal-organic framework (2D MOF) molecular sieve membranes are promising due to their tunable structures, ultrathin thickness, and customizable pores - ideal for applications such as gas separation and deionization. However, their practical development has been severely hindered by time, consuming synthesis processes and inefficient assembly methods.

In a study published in National Science Review, a research team led by Prof. YANG Weishen and Prof. PENG Yuan from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) developed a triggered interfacial synthesis strategy that accelerates the fabrication of high-performance MOF membranes.

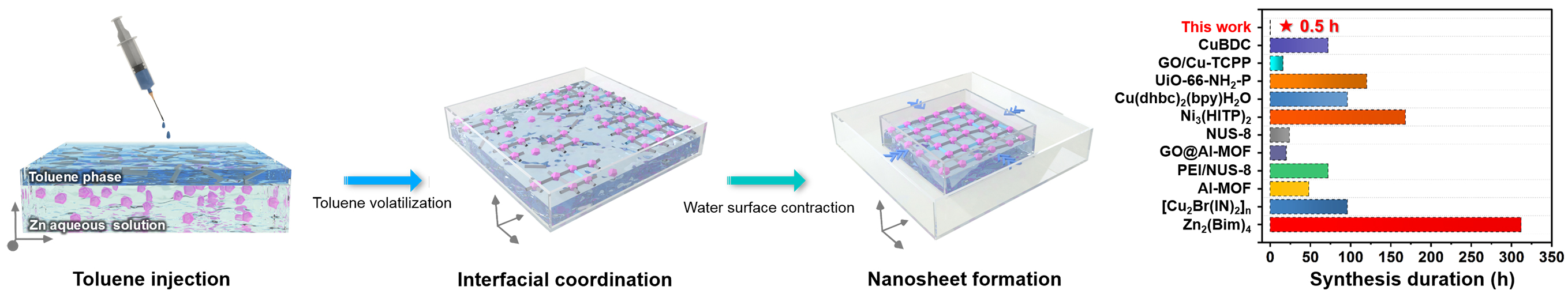

Water surface contraction boosted the air-water interfacial coordination strategy for the most rapid fabrication record of 2D MOF membranes (Image by Peng Yuan)

The strategy combines confined air–water interfacial nanosheet synthesis with a radial thrust-triggered in situ assembly, reducing fabrication time from hours or days to just minutes. The process requires only microliter-scale consumption of organic ligands, offering a cost-effective and scalable pathway.

Using this strategy, researchers fabricated a Zn-MOF nanosheet membrane that achieved a H2 and CO2 separation factor of 210 and hydrogen permeance of 6.2 × 10−7 mol/m2•s•Pa, outperforming both conventional MOF membranes and commercial alteratives. These results represent state-of-the-art performance and demonstrate the feasibility of on-demand design of ultrathin 2D MOF membranes for industrial applications.

Beyond membrane performance, this strategy exhibits remarkable versatility. By flexibly combining different metal ions and organic ligands, the researchers synthesized 12 types of MOF nanosheets with distinct framework structures and pore/channel environments. These results provide a novel approach for the application-oriented and customizable fabrication across a wide range of eparation scenarios.

"This work not only provides a new strategy for efficiently customization of MOF nanosheets, but also expands the application potential of the ultrathin, flexible 2D materials with high-density, regular pore arrays in material science, device architecture design, separation engineering," said Prof. YANG.