Research News

-

07 21, 2017Scientists Design New Lithium-Sulfur Battery ElectrolyteThe research group of Energy Storage Technology Research Department, which is led by ZHANG Huamin, LI Xianfeng and ZHANG Hongzhang from Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), designed a new LiNO3-free electrolyte.This novel electrolyte has low solubility (Ksp) of polysulfide as well as stable SEI film on lithium, which enabled high stability, safety and capacity output of Li-S batteries.

07 21, 2017Scientists Design New Lithium-Sulfur Battery ElectrolyteThe research group of Energy Storage Technology Research Department, which is led by ZHANG Huamin, LI Xianfeng and ZHANG Hongzhang from Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), designed a new LiNO3-free electrolyte.This novel electrolyte has low solubility (Ksp) of polysulfide as well as stable SEI film on lithium, which enabled high stability, safety and capacity output of Li-S batteries.

The topic of Lithium-Sulfur (Li-S) batteries has become one of the hottest international research spots due to the high energy density and the low cost properties of Li-S batteries. Currently, the shuttle effect of polysulfide and the unstable interface of lithium anode are the key issues, which obstruct the development of Li-S batteries.

For a long time, scientists are used to utilize LiNO3 additive to solve the polysulfide shuttle problem in Li-S battery. However, it also brings in potential safety hazard due to nitrate, carbon and sulfur coexistence in battery system.

To solve this problem, the research group of Energy Storage Technology Research Department, which is led by ZHANG Huamin, LI Xianfeng and ZHANG Hongzhang from Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), designed a new LiNO3-free electrolyte.

This novel electrolyte has low solubility (Ksp) of polysulfide as well as stable SEI film on lithium, which enabled high stability, safety and capacity output of Li-S batteries. And the results were published in Nano Energy, 39, 262–272.

LiNO3-free electrolyte with low solubility of polysulfide and low dendrite of lithium for Li-S battery(Image by QU Chao and CHEN Yuqing)

This is the firstly reported LiNO3–free electrolyte with high-performance: Low Ksp of polysulfide, high conductivity, high active materials utilization, and excellent anode interface stability.

Scientists have tried to assemble 4000 mAh soft package Li-S battery with this electrolyte. And it could realize the high energy density of 350 Wh/kg, the high power density of 60 W/kg, and 30-cycled stable circulation. Such battery is expected to make solar unmanned aircraft flight one month in a row.

Meanwhile, this work provides a new idea for design and preparation of Li-S batteries electrolyte.

The above research work was supported by the National Natural Science Foundation of China, the Collaborative Innovation Centre of Chemistry for Energy Materials of the Ministry of Education (iChEM), the Youth Innovation Promotion Association of the Chinese Academy of Sciences and the Youth Innovation Foundation of Dalian Institute of Chemical Physics. (Text by QU Chao and CHEN Yuqing)

Dr. WANG Yongjin

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84374221

E-mail: wangyj@dicp.ac.cn

-

07 19, 2017One-Step Device Fabrication of Phosphorene and Graphene: Accelerates New-concept Energy Storage SystemsThe development of flexible display, wearable electronics and foldable phones have attracted more and more attentions. To date, it is not only a concept but also a real commercial product in the market. The development of these lightweight and flexible smart electronics urgently calls for the adaptive new-concept energy storage devices.

07 19, 2017One-Step Device Fabrication of Phosphorene and Graphene: Accelerates New-concept Energy Storage SystemsThe development of flexible display, wearable electronics and foldable phones have attracted more and more attentions. To date, it is not only a concept but also a real commercial product in the market. The development of these lightweight and flexible smart electronics urgently calls for the adaptive new-concept energy storage devices.

The development of flexible display, wearable electronics and foldable phones has attracted more and more attention. To date, it is not only a concept but also a real commercial product in the market. The development of these lightweight and flexible smart electronics urgently calls for the adaptive new-concept energy storage devices.

Flexible micro-supercapacitors (MSCs) exhibit the properties of short ion diffusion distance, high power density, superior cycling lifetime, robust mechanical flexibility and high safety. They are considered as one of the most promising power sources candidates for full integration into the manufacturing process of electronics.

Scientists WU Zhongshuai, BAO Xinhe and et al. from Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), collaborated with REN Wencai and CHENG Huiming from Institute of Metal Research of CAS, developed a simple approach to fabricate flexible MSCs. Such devices can be used as the new-concept energy storage system and can accelerate the development of flexible electronics.

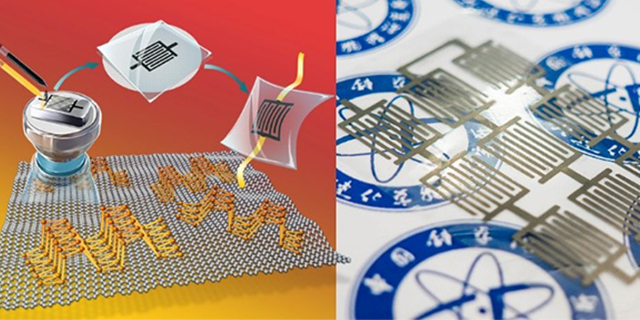

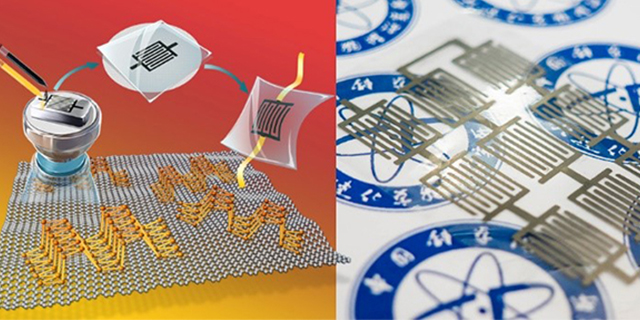

Illustration of simplified fabrication of phosphorene/graphene planar MSCs and the demonstration of serially interconnected MSCs (Image by XIAO Han and ZHAO Xuejun)

These new-developed interdigital patterned MSCs were based on stacking high-qualified few-layer phosphorene nanosheets and electrochemically exfoliated graphene in ionic liquid electrolyte, which exhibited a high-energy density and excellent flexibility. Moreover, these flexible MSCs showed good stability without capacitance fluctuation even under highly folded states.

The fabrication method of these obtained MSCs was much simple compared with previous MSCs fabrication process: The interdigital electrode patterns can be obtained by only one-step-mask assistance filtration. The hybrid phosphorene and graphene films with interdigital patterns were manufactured by layer-by-layer deposition of phosphorene and graphene nanosheets. A customized interdigital mask assistance is needed during this process. Then the films were directly transferred onto a flexible substrate.

Scientists found that these patterned phosphorene and graphene films present good properties of uniformity, flexibility, conductivity (319 s/cm) and structural integration. The energy density of this MSCs can reach to as high as 11.6 mWh cm-3 in ionic liquid electrolyte.

In addition, the fabrication method of MSCs is not only very simple, but also highly flexible for simplified production of parallel and serial interconnected modular power sources, without need of conventional metal-based interconnects and contacts, for designable integrated circuits with high output current and voltage.

The above work was published online in ACS Nano(DOI: 10.1021/acsnano.7b03288). It was funded by Ministry of Science and Technology of China, National Natural Science Foundation of China, Natural Science Foundation of Liaoning Province and DICP, and China Postdoctoral Science Foundation. (Text and Image by XIAO Han and ZHAO Xuejun)

Dr. WANG Yongjin

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84374221

E-mail: wangyj@dicp.ac.cn -

07 19, 2017One-Step Device Fabrication of Phosphorene and Graphene: Accelerates New-concept Energy Storage SystemsThe development of flexible display, wearable electronics and foldable phones have attracted more and more attentions. To date, it is not only a concept but also a real commercial product in the market. The development of these lightweight and flexible smart electronics urgently calls for the adaptive new-concept energy storage devices.

07 19, 2017One-Step Device Fabrication of Phosphorene and Graphene: Accelerates New-concept Energy Storage SystemsThe development of flexible display, wearable electronics and foldable phones have attracted more and more attentions. To date, it is not only a concept but also a real commercial product in the market. The development of these lightweight and flexible smart electronics urgently calls for the adaptive new-concept energy storage devices.

The development of flexible display, wearable electronics and foldable phones has attracted more and more attention. To date, it is not only a concept but also a real commercial product in the market. The development of these lightweight and flexible smart electronics urgently calls for the adaptive new-concept energy storage devices.

Flexible micro-supercapacitors (MSCs) exhibit the properties of short ion diffusion distance, high power density, superior cycling lifetime, robust mechanical flexibility and high safety. They are considered as one of the most promising power sources candidates for full integration into the manufacturing process of electronics.

Scientists WU Zhongshuai, BAO Xinhe and et al. from Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), collaborated with REN Wencai and CHENG Huiming from Institute of Metal Research of CAS, developed a simple approach to fabricate flexible MSCs. Such devices can be used as the new-concept energy storage system and can accelerate the development of flexible electronics.

Illustration of simplified fabrication of phosphorene/graphene planar MSCs and the demonstration of serially interconnected MSCs (Image by XIAO Han and ZHAO Xuejun)

These new-developed interdigital patterned MSCs were based on stacking high-qualified few-layer phosphorene nanosheets and electrochemically exfoliated graphene in ionic liquid electrolyte, which exhibited a high-energy density and excellent flexibility. Moreover, these flexible MSCs showed good stability without capacitance fluctuation even under highly folded states.

The fabrication method of these obtained MSCs was much simple compared with previous MSCs fabrication process: The interdigital electrode patterns can be obtained by only one-step-mask assistance filtration. The hybrid phosphorene and graphene films with interdigital patterns were manufactured by layer-by-layer deposition of phosphorene and graphene nanosheets. A customized interdigital mask assistance is needed during this process. Then the films were directly transferred onto a flexible substrate.

Scientists found that these patterned phosphorene and graphene films present good properties of uniformity, flexibility, conductivity (319 s/cm) and structural integration. The energy density of this MSCs can reach to as high as 11.6 mWh cm-3 in ionic liquid electrolyte.

In addition, the fabrication method of MSCs is not only very simple, but also highly flexible for simplified production of parallel and serial interconnected modular power sources, without need of conventional metal-based interconnects and contacts, for designable integrated circuits with high output current and voltage.

The above work was published online in ACS Nano(DOI: 10.1021/acsnano.7b03288). It was funded by Ministry of Science and Technology of China, National Natural Science Foundation of China, Natural Science Foundation of Liaoning Province and DICP, and China Postdoctoral Science Foundation. (Text and Image by XIAO Han and ZHAO Xuejun)

Dr. WANG Yongjin

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84374221

E-mail: wangyj@dicp.ac.cn -

07 19, 2017International Young Scientist Symposium on Catalytic Biomass Conversion (IYCBC 2017) is held in DICP

07 19, 2017International Young Scientist Symposium on Catalytic Biomass Conversion (IYCBC 2017) is held in DICP

From July 16th to 18th, 2017, DICP Symposium (XLIV) on International Young Scientist Symposium on Catalytic Biomass Conversion was held in Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS). The chairmen of this symposium were Prof. WANG Feng from DICP and Prof. Carsten Sievers from Georgia Institute of Technology.

CAI Rui, who is the deputy director general of DICP delivered a speech on the opening ceremony. He briefly introduced the current research and progress in DICP.

More than twenty scientists from China, the United States, Sweden, Netherland, Japan and Singapore were invited to present brilliant research reports on the symposium and they had a warm discussion with the participants.

The symposium aims to promote research and development in the field of catalytic biomass conversion and focuses on a number of cutting-edge topics in this field: the conversion and utilization of native biomass, the production of chemicals and fuels from lignocellulose, the mechanism of biomass conversion process, the spectral characterization of the catalysts, and the applications of theoretical calculations in biomass conversion.

The participants also visited the General Testing and Analysis group in DICP and Dalian science and technology innovation park of CAS, and conducted in-depth discussion on international cooperation and academic exchanges.

This forum strengthens the exchange and cooperation between DICP and the relevant scientific research institutions on catalytic biomass transformation and enhances the international influence of DICP in this research area. It will also promote the development of biomass conversion in DICP. (Text by LIU Huifang, Image by ZAHNG Chaofeng and ZHAO Zhitong)

-

07 19, 2017International Young Scientist Symposium on Catalytic Biomass Conversion (IYCBC 2017) is held in DICP

07 19, 2017International Young Scientist Symposium on Catalytic Biomass Conversion (IYCBC 2017) is held in DICP

From July 16th to 18th, 2017, DICP Symposium (XLIV) on International Young Scientist Symposium on Catalytic Biomass Conversion was held in Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS). The chairmen of this symposium were Prof. WANG Feng from DICP and Prof. Carsten Sievers from Georgia Institute of Technology.

CAI Rui, who is the deputy director general of DICP delivered a speech on the opening ceremony. He briefly introduced the current research and progress in DICP.

More than twenty scientists from China, the United States, Sweden, Netherland, Japan and Singapore were invited to present brilliant research reports on the symposium and they had a warm discussion with the participants.

The symposium aims to promote research and development in the field of catalytic biomass conversion and focuses on a number of cutting-edge topics in this field: the conversion and utilization of native biomass, the production of chemicals and fuels from lignocellulose, the mechanism of biomass conversion process, the spectral characterization of the catalysts, and the applications of theoretical calculations in biomass conversion.

The participants also visited the General Testing and Analysis group in DICP and Dalian science and technology innovation park of CAS, and conducted in-depth discussion on international cooperation and academic exchanges.

This forum strengthens the exchange and cooperation between DICP and the relevant scientific research institutions on catalytic biomass transformation and enhances the international influence of DICP in this research area. It will also promote the development of biomass conversion in DICP. (Text by LIU Huifang, Image by ZAHNG Chaofeng and ZHAO Zhitong)

-

07 01, 2017The 8th International Flow Battery Forum Has Been Held in Manchester, U.K

07 01, 2017The 8th International Flow Battery Forum Has Been Held in Manchester, U.K

The 8th international flow battery forum (IFBF) has been held in Manchester, U.K. from June 27 to 29 in 2017. More than 300 participants all over the world who are from flow battery R&D companies, materials suppliers, energy storage users and academic institutions attended this meeting.

Three keynote talks were presented in this meeting. Prof. Maria Skyllas-Kazacos who is from the University of New South Wales is the founder of vanadium flow battery. He introduced the increased requirement of energy storage capacity in Australia and the R&D of vanadium flow battery technology to date.

Professor ZHANG Huamin from Dalian Institute of Chemical Physics (DICP) of Chinese Academy of Sciences (CAS) is the person who firstly industrialized vanadium flow battery technology. He introduced the recent progress on the fundamental research and industrial applications of flow battery by DICP/Rongke Power. His introductions of the capacity of 300MW/year of Rongke Equipment Company and the 200MW/800MWh vanadium flow battery power station attracted lots of attetions and were highly praised by the attendee.

Professor Michael Aziz from Harvard University introduced the development and challenge of new types of aqueous organic and organic metal flow batteries.

The hot topics in this meeting are market environment, policy, business model and application popularity of energy storage.

This meeting is beneficial for the further understanding and communication of flow battery technology among the flow battery R&D companies, materials suppliers, energy storage users and academic institutions. It can accelerate the development of flow battery technology significantly. (Text and Image by YUE Meng and ZHENG Qiong)