Research News

-

11 26, 2018Alliance with 2D Materials Boosts Sulphur-based Batteries

11 26, 2018Alliance with 2D Materials Boosts Sulphur-based Batteries

Shuttling stoppers: Cross-section scanning electron microscopy image of exfoliated graphene (EG)/Co(OH)2 interlayer/polypropylene(PP) separator. (Image by Journal of Physics: Energy)

Sulphur has recently proved a cheap and competitive partner for lithium ion batteries with an energy density of 2600 Wh/kg, in theory. In practice lithium-sulphur batteries have suffered from low cycling lifetimes attributed to the polysulphide ions shuttling to and from the electrodes during charge and discharge. Now researchers at the Dalian Institute of Chemical Sciences, the Chinese Academy of Science, have developed a hybrid interlayer combining graphene and Co(OH)2 nanosheets that prevents sulphide movement and enhances use of the sulphide ions to improve the battery capacity and cyclability.

Reporting their results in the first issue of the Journal of Physics: Energy Zhong-Shuai Wu and colleagues highlight the electrical insulation of elemental sulphur and the discharge products Li2S/Li2S2, as a challenge for optimizing performance, as well as the sulphide ion shuttling, which alongside volumetric expansion and lithium dendrite formation diminish the cycling lifetime.

Zhong-Shuai Wu (Image by physicsworld)

Interlayer innovations

Other groups have previously experimented with modifying the separator – a standard battery component between cathode and anode – with nonpolar carbon materials to prevent the sulphide ion shuttling. However, the interactions between sulphide ions and those modified separators were too weak to effectively block their diffusion. Wu and colleagues get around this with the hybrid interlayer they coat on the separator because the Co(OH)2 nanosheets are polar and so increase chemical interactions with the sulphides, while the graphene nanosheets serve as a physical barrier for preventing the diffusion and migration of the dissolved polysulfides. The high functionality of the graphene and Co(OH)2 nanosheets with a strong synergistic effect for suppressing the shuttle effect also allows low mass loading of just 0.20 mg cm-2.

“The EG [exfoliated graphene] sheets in hybrid interlayer can serve as a polysulfides physical barrier and electrical conductive network to increase the reuse of polysulfide trapped while the polar Co(OH)2 nanosheets can fulfil the role of chemical adsorption of polysulfides,” they explain in their report. “As a consequence, high-capacity Li-S batteries with 918 mAh/g at 0.5 C, accompanied with exceptional rate capability (677 mAh/g at 5 C) and stable cycle stability (565 mAh/g after 300 cycles at 0.5 C), are achieved.”

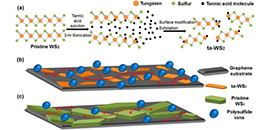

Tannic WS2 enhancements: (a) Schematic representation for effective exfoliation and modification of pristine WS2 with tannic acid assistant. (b) and (c) Schematic illustration of polysulfide species on the graphene mixed with ta-WS2 and pristine WS2, respectively. (Image by Journal of Physics: Energy)

Optimizing reaction rates

Da-Wei Wang at the University of New South Wales in Australia and Xin Tan at Australian National University and colleagues also report results of research focused on polysulphide batteries in the first issue of Journal of Physics: Energy. They suggest, “Although substantial effort has been devoted to the improvement of LIBs [lthium ion batteries] and various vigorous studies toward further development still continue, the present Li-ion technologies cannot fulfil the ever-increasing requirements of the modern society, because of the limited energy density and expensiveness in the large-scale applications.”

They add that the main barrier to uptake for polysulphide organic battery systems is the cost and flammability, which has prompted a lot of effort to make organic polysulphide systems that operate with an aqueous-based electrolyte. This has in turn led to frustrations with “sluggish” reaction rates. Wang and Tan and their colleagues tackle this with a conducting graphene support decorated with hydrophilic WS2 nanosheets exfoliated using tannic acid. In their report they highlight that as well as enabling efficient exfoliation of WS2 nanosheets, the tannic acid modifies them to enhance the hydrophilic properties thereby improving the electrocatalytic activity of the WS2 and boosting the battery reaction rates.

“The incorporation of tannic acid imposed the collective interactions between polysulfide and the WS2 nanosheets via the hydrophilic molecules and the polar surfaces,” they explain in their report. “With a 0.5 M Li2S2 electrolyte, the graphene and modified WS2 mixture gave an areal specific capacity of 0.37 mA h/cm2, compared to 0.27 mA h/cm2 for the pure graphene.”

Full details of both papers are available in the first issue of Journal of Physics: Energy. (physicsworld) -

11 26, 2018Scientist Found Strong Metal-Support Interaction Effect in Au/Carbide CatalystsRecently, a research group led by Prof. FU Qiang and Prof. BAO Xinhe from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences demonstrated the strong metal-support interaction (SMSI) effect in molybdenum carbide-supported Au catalyst (Au/MoCx).

11 26, 2018Scientist Found Strong Metal-Support Interaction Effect in Au/Carbide CatalystsRecently, a research group led by Prof. FU Qiang and Prof. BAO Xinhe from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences demonstrated the strong metal-support interaction (SMSI) effect in molybdenum carbide-supported Au catalyst (Au/MoCx).

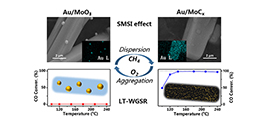

Recently, a research group led by Prof. FU Qiang and Prof. BAO Xinhe from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences demonstrated the strong metal-support interaction (SMSI) effect in molybdenum carbide-supported Au catalyst (Au/MoCx).

SMSI has been regarded as one of the most important concepts in heterogeneous catalysis. The classical SMSI phenomena are widely observed for platinum group metals (PGMs) supported on reducible oxides such as TiO2, CeO2, and Fe2O3 upon high-temperature reduction treatments.

Transition-metal carbides (TMCx) exhibit noble-metal-like electronic properties, which are promising as catalytic materials or catalyst supports in many reactions. Recently, there is a call for studies of the SMSI effect in metal/carbide systems in order to extend the important concept and to elucidate the nature of metal-carbide interactions.

Strong Metal-Support Interaction (SMSI) effect has been well demonstrated in metal/carbide catalysts induced by carbonization of metal/oxide catalysts. (Image by DONG Jinhu)

In this work, both Au catalyst and MoCx support were chosen to construct the metal/carbide interfaces. The scientists found that Au remained highly dispersed on the carbide support, interacted with the support via strong charge transfer, and more importantly showed excellent low-temperature water-gas shift reaction (LT-WGSR) activity. Oxidation treatment of the Au/MoCx catalysts led to strong aggregation of Au nanoparticles and lower LT-WGSR activity.

These results confirmed that the SMSI effect was active in metal catalysts supported on carbides, which showed reversibility under alternative oxidation and carbonization treatment conditions. In-situ characterization methods were used to study the evolution process during the carburization. It was proposed that epitaxy between Au and MoOxCy played an important role in wetting and stabilization of Au on the carbide support.

The finding opens a new territory for the concept, which is of great significance for understanding of the SMSI effect and effective modulation of catalysis over carbide-supported metal catalysts.

The above work entitled “Carbide-Supported Au Catalysts for Water–Gas Shift Reactions: A New Territory for the Strong Metal–Support Interaction Effect” was published in the Journal of the American Chemical Society.

The work was supported by the National Natural Science Foundation of China, the Strategic Priority Research Programme of the CAS, National Key Projects for Fundamental Research and Development of China, and Collaborative Innovation Center of Chemistry for Energy Materials (iChEM). (Text by DONG Jinhu) -

11 14, 2018Selective Synthesis of Aromatics from CO2

11 14, 2018Selective Synthesis of Aromatics from CO2

Fossil resources are used as a feedstock for many important processes in the chemical industry—however, they are limited. CO2, in contrast, could be used as a renewable feedstock for the production of chemicals. CO2 hydrogenation could provide fuels as well as chemicals such as methanol, olefins, or aromatics. C1 compounds such a methane or methanol can already be selectively synthesized from CO2 and H2. A selective hydrogenation of CO2 to give aromatics, in contrast, had not been achieved so far.

Wenliang Zhu, Zhongmin Liu, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, and colleagues have developed a composite catalyst made from the oxide ZnAlOx and the zeolite H-ZSM-5 for the selective synthesis of aromatics (example pictured) from CO2 and H2. The team synthesized the ZnAlOx using a co-precipitation method. The zeolite was prepared from commercially available Na-ZSM-5 by ion exchange. The composite catalyst was then prepared by physical mixing of the two components in a 1:1 ratio.

Selective synthesis of aromatics. (Image by ChemistryViews)

Hydrogenation reactions were then performed over the composite catalyst using a gas mixture of CO2, H2, and argon (H2/CO2/Ar = 3/1/0.2) at a combined pressure of 3 MPa and at a temperature of 593 K. The team achieved up to 9 % CO2 conversion with a selectivity of aromatics among the carbon products (excluding CO) up to 74 %. The CH4 selectivity was only 0.4 %. According to the proposed mechanism, intermediates such as methanol and dimethyl ether are first formed on the ZnAlOx surface and then transmitted to H-ZSM-5 and converted into olefins and aromatics. (ChemistryViews) -

11 14, 2018Large Perovskite Single Crystals Take it Slow

11 14, 2018Large Perovskite Single Crystals Take it Slow

Single-crystalline organolead halide perovskites possess optoelectronic properties that make them highly attractive for a range of applications including solar cells, light-emitting diodes, lasers, and photodetectors. But the growth of large, high-quality single crystals of perovskite has proved difficult. Now researchers from Shaanxi Normal University, Dalian Institute of Chemical Physics, and Xi’an Jiaotong University in China have devised a simple means of producing centimeter-sized single crystals [Liu et al., Materials Today (2018),].

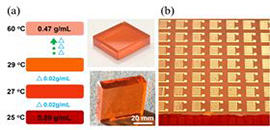

(a) Photos of MAPbBr3 single crystals grown using the LTGC process. (b) Photo of planar photodetectors based on high quality MAPbBr3 single crystals. (Image by materialstoday)

“The practical application of single-crystalline organolead halide perovskite materials is currently limited by the lack of a method for preparing high quality perovskite single crystals of large dimensions,” explains Kui Zhao, who led the research along with Shengzhong Liu.

Theoretical predictions have indicated that keeping the rate of temperature change extremely slow during growth should restrict conditions to the optimal single-crystal growth zone (OSCG). In effect, by curtailing extraneous nucleation, single crystal growth should be maximized. Now Zhao, Liu, and their colleagues have developed a low temperature-gradient crystallization (LTGC) method that can, as predicted, produce single crystals of the perovskite CH3NH3PbBr3 (MAPbBr3) over 2-inches in diameter.

“With conventional methods, the size of single crystals is limited to less than half an inch and their crystalline quality remains unsatisfactory for demanding applications,” says Zhao. “We have demonstrated well-controlled growth conditions that lie within the OSCG zone.”

The simple method starts with the mixing of precursor materials MABr and PbBr2 in a solvent for 24 hours to ensure complete dissolution. After a seed crystal is added to the solution, it is gently heated from 25°C to 60°C at a gradual rate of 2°C a day. By controlling the solute diffusion rate, very slow crystal growth minimizes the defect density, producing large and high quality single crystals after around 20 days.

“Our single crystals exhibit the best optoelectronic qualities of all MAPbBr3 materials reported in the literature, including ultralow trap state density, extremely high mobility, carrier lifetime, and diffusion length,” says Zhao.

The combination of large absorption coefficient, long electron-hole diffusion length, high carrier mobility, and superior tolerance to defects renders the single crystals particularly advantageous for optoelectronic applications.

To demonstrate the potential of the MAPbBr3 single crystals, the team created high-performance planar photodetectors with high external quantum efficiency, excellent detectivity, and fast response speed.

“To our knowledge, both the detectivity and the response speed are the best among all MAPbBr3 devices reported to date,” Zhao told Materials Today.

The team is now exploring the applicability of the growth method to other kinds of perovskite single crystals, such as ABX3 (PEA2PbI4), which could be useful for high-resolution image sensors and X-ray detectors. (materialstoday) -

11 14, 2018Single-manganese-atom Catalyst Drives Key Water-splitting Step

11 14, 2018Single-manganese-atom Catalyst Drives Key Water-splitting Step

Finding may advance mission to make hydrogen fuel from water inexpensively

An easy-to-prepare catalyst consisting of isolated metal atoms embedded at various points across functionalized graphene sheets can carry out a key step in water splitting, according to a study (Nat. Catal. 2018, DOI: 10.1038/s41929-018-0158-6).

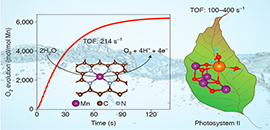

Graphene functionalized with isolated MnN4 units undergoes a catalytic cycle to convert water (starting at top right) to O2 (top left). (Image by Nat. Catal.)

If water could be split easily and inexpensively into molecular hydrogen (H2) and oxygen (O2), the world could draw a nearly limitless supply of clean-burning hydrogen fuel from the oceans. Inspired by nature’s use of a metal cluster (CaMn4O5) to generate O2 from water during photosynthesis, scientists have designed various multimetal-atom catalysts to facilitate the process, called the water oxidation reaction (WOR).

Several researchers have shown that various synthetic manganese-cluster catalysts actively mediate WOR. What remained unknown is whether a simpler, less expensive catalyst based on single manganese atoms rather than clusters can do the job actively and energy efficiently.

Yes, it can, concludes a team led by Can Li of the Dalian Institute of Chemical Physics. By reacting manganese chloride, graphene oxide, and ammonia, the researchers made a material in which isolated manganese atoms are embedded across a graphene surface, each surrounded by four nitrogen atoms. The team conducted water-oxidation tests to evaluate the material’s catalytic properties.

The researchers found that in contrast with pure graphene and nitrogen-doped graphene, which were inactive, their MnN4-graphene catalyst exhibited a WOR turnover frequency of up to 215 per second. Turnover frequency is a measure of catalytic activity that describes how many times a catalyst carries out a reaction in a given period. The MnN4-graphene value is nearly 100 times as high as that of other synthetic Mn-based catalysts and in the ballpark of naturally occurring ones. The team also found that the new catalyst mediates WOR at relatively low overpotential values, an indication of high energy efficiency.

A great deal of effort has been devoted to finding efficient, low-cost catalysts that drive water splitting, says Xiao Cheng Zeng of the University of Nebraska, Lincoln, who has studied the process computationally. “The water oxidation reaction is the most challenging step,” he says, so this experimental demonstration with manganese, which is much cheaper than precious-metal catalysts, “is a significant step in the right direction.” (c&en) -

10 29, 2018“Milder” Ammonia Synthesis Method Should Help EnvironmentA Chinese research team has developed a “milder” way to synthesize ammonia by requiring lower temperature and pressure than the current method. The process offers great promise for saving energy and reducing carbon dioxide emissions.

10 29, 2018“Milder” Ammonia Synthesis Method Should Help EnvironmentA Chinese research team has developed a “milder” way to synthesize ammonia by requiring lower temperature and pressure than the current method. The process offers great promise for saving energy and reducing carbon dioxide emissions.

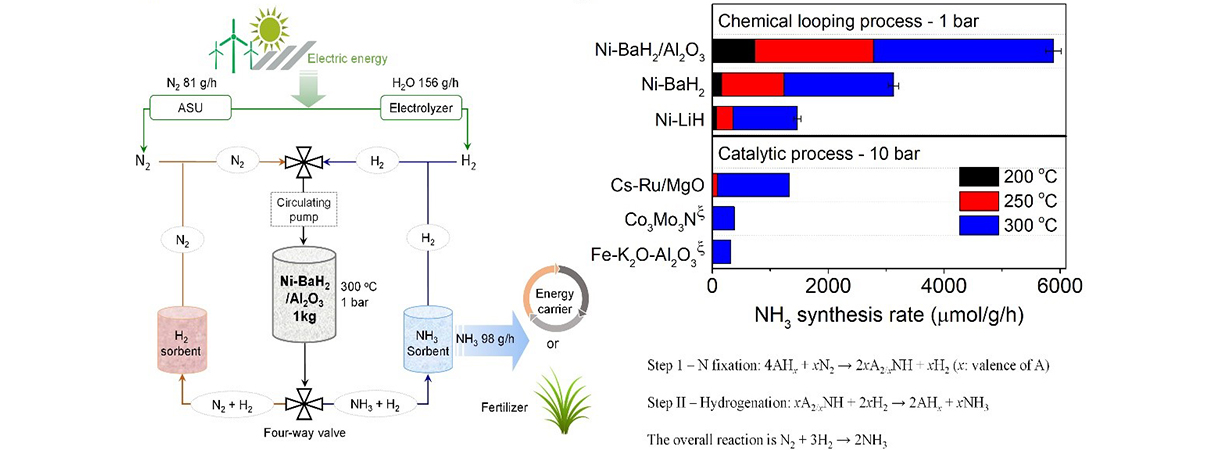

A Chinese research team has developed a “milder” way to synthesize ammonia by requiring lower temperature and pressure than the current method. The process offers great promise for saving energy and reducing carbon dioxide emissions.

The new process was developed by a research team led by Prof. CHEN Ping and Dr. GUO Jianping from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences. It involves a new chemical looping method based on metal hydride and imide. The process operates at atmospheric pressure and 100-350°C, in contrast with the Haber-Bosch process – currently dominating world ammonia production – which operates at 100-200 bars and 350-450°C.

Ammonia helps feed humanity through its role in producing nitrogen fertilizer. It also has the potential to store and transport renewable energy. However, current ammonia production is very energy intensive – consuming 1-2% of world energy output. In addition, about 1.9 metric tons of carbon dioxide are produced for every metric ton of ammonia.

Production of ammonia via a chemical looping process (Image by GAO Wenbo)

“In order to address the challenges of the energy and environmental crisis, we developed an alternative process for ammonia synthesis from nitrogen gas, water and renewable energy,” said CHEN, the study’s lead researcher.

The process uses alkali and alkaline earth metal imides as nitrogen carriers that mediate ammonia production via a two-step chemical looping process operating under mild conditions.

“In the first step, nitrogen was fixed through the reduction of nitrogen gas by alkali or alkaline earth metal hydrides to form imides,” said CHEN. “In the second step, the imides were hydrogenated to produce ammonia and regenerated the metal hydrides.”

CHEN explained that the two steps could be accelerated by the catalysis of transition metals. “The chemical loop mediated by BaNH and catalyzed by Ni could produce ammonia in the temperature range of 100 to 350°C and atmospheric pressure. The production rate of ammonia was more than one order of magnitude higher than that of the thermocatalytic process,” CHEN added.

CHEN noted that the study provides a “promising solution to the efficient harvest and storage of renewable energy.” CHEN said the process has the advantage of operating at atmospheric pressure and also offers a means of synthesizing ammonia in a localized, distributed manner.

Dr. WANG Yongjin

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84374221

E-mail: wangyj@dicp.ac.cn