The popularity of electric vehicles is accelerating the move toward sustainable energy, but millions of end-of-life electric vehicles generated over the next decade pose serious waste management challenges, especially the recycling of spent batteries.

Recently, a research group led by Prof. CHEN Zhongwei from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) realized two regeneration routes for scalable and affordable recycling of spent batteries into new lithium-ion batteries (LIBs) and their alternatives.

This study was published in Nature Sustainability.

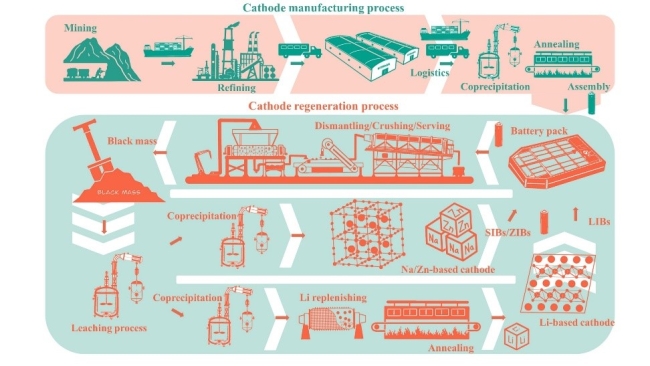

Various cathode regeneration processes (Image by YANG Tingzhou)

In this study, the researchers designed various cathode regeneration methods to recover all high-value elements from Black mass and repurposed them to manufacture new cathode materials for LIBs and post-LIBs, enabling the transition to next-generation sustainable battery systems.

"The obtained cathode materials for LIBs and transition metal cyanide complex for post-LIBs with optimized microstructure and matched capacity are comparable to or better than commercial ones. Compared to battery packs with commercial materials, the manufacturing costs for LIB and post-LIB packs using our regenerated materials have dropped to an all-time low cost, accompanied by significantly reduced impacts on human health, ecosystem quality, and resource scarcity," said Prof. CHEN.

This work was supported by the Power Battery & System Research Center from State Key Laboratory of Catalysis, DICP Foundation, the Dalian Revitalization Talents Program, and the Liaoning Binhai Laboratory. (Text by SHI Xin)