A research team led by Prof. WU Zhong-Shuai from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences has developed all-3D printed Li metal batteries (LMBs) with robust cycle stability and ultrahigh areal energy density.

The LMBs take a porous and conductive Ti3C2Tx MXene skeleton for dendrite-free and stable Li metal anode and multi-dimensionally conductive LiFePO4 (LFP) lattice as ultra-thick cathode.

This study was published in Energy Storage Materials on Oct. 19.

LMBs are considered as a class of high-energy-density systems beyond current state-of-the-art lithium-ion batteries. Nevertheless, the uncontrollable dendrite growth and huge volume change of Li metal anodes have raised poor cycle life.

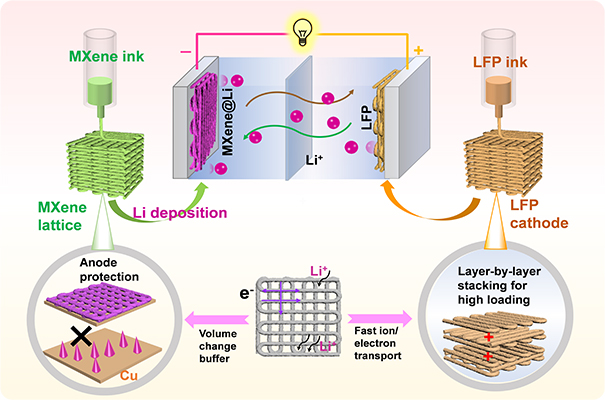

Schematic illustration of the fabrication process of 3D printed LMBs (Image by MA Jiaxin and ZHENG Shuanghao)

In this study, the researchers reported an all-3D printing approach for constructing ultrahigh-performance LMBs. The LMBs were comprised of a dendrite-free Li metal anode with porous MXene lattices to regulate local current distribution, which homogenized the lithium nucleation, and a 3D conductive porous LFP framework cathode to achieve fast ion/electron transfer channels.

Due to the abundance of Li nucleation sites and large pore volume in the MXene lattices, the 3D printed MXene scaffolds prevented the infinite volume change and dendritic formation of Li anodes.

Furthermore, by pairing ultra-thick LFP cathodes lattices with high-efficiency electron and ion networks, the all-3D printed LFP||MXene@Li LMBs delivered unprecedented areal capacity (25.3 mAh/cm2) and energy density (81.6 mWh/cm2) under an ultrahigh mass loading of 171 mg/cm2, exceeding all reported 3D printed batteries so far.

This work was supported by the National Natural Science Foundation of China, the Strategic Priority Research Program of CAS, and Dalian National Laboratory for Clean Energy of CAS. (Text by MA Jiaxin and ZHENG Shuanghao)