Ferroelectrics are photocatalytic candidates for solar fuel production. However, the performance of ferroelectric photocatalysts is often moderate, which could not achieve overall water splitting.

Recently, a research team led by Prof. LI Can and Prof. FAN Fengtao from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) proposed a new charge separation strategy to fabricate interfacial charge-collecting nanostructures on positive and negative domains of ferroelectric, which enables water splitting in ferroelectric photocatalysts.

This study was published in Nature Communications on July 22.

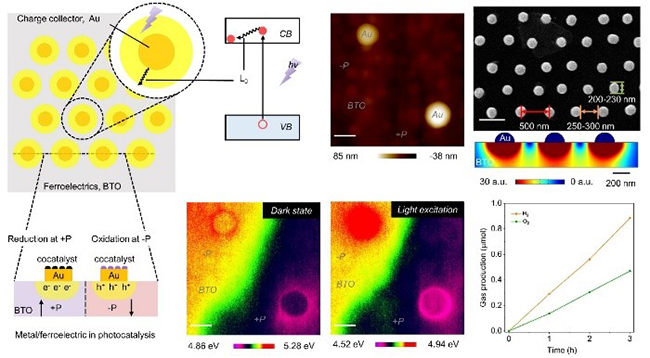

Bipolar charge collecting structure enables overall water splitting on ferroelectric photocatalysts (Image by LIU Yong)

The researchers chose the ferroelectric BaTiO3 single domain crystal and Au nanoparticle as a model system to highlight the charge separation mechanism at Au/BaTiO3 interface. They observed that photogenerated electrons and holes accumulated efficiently within their thermalization length (around 50 nm) around Au nanoparticles located in the positive and negative domains of a BaTiO3 single crystal, respectively.

They found that the measured thermalization length was an essential experimental prescription for fabricating high-efficiency photocatalytic and photovoltaic devices on the nanoscale. With this structure design, constructed ferroelectric photocatalysts could perform photocatalytic overall water splitting.

"The fabrication of bipolar charge-collecting structures on ferroelectrics to achieve overall water splitting may set a paradigm for utilizing the energetic photogenerated charges in solar energy conversion," said Prof. FAN.

The above work was supported by the Fundamental Research Center of Artificial Photosynthesis (FReCAP), the National Natural Science Foundation of China, CAS Projects for Young Scientists in Basic Research, the National Key R&D Program of China, DICP Innovation Foundation and Fellowship of China Postdoctoral Science Foundation. (Text by LIU Yong)