Poly (1,4-cyclohexylene dimethylene terephthalate-co-isophthalate) (PCTA) is an important copolyester that has been widely used in cosmetic containers, home appliances, and medical packaging.

Currently, PCTA is manufactured via polycondensation of cyclohexanedimethanol (CHDM), which is industrially produced from petroleum-derived xylene. To reduce the reliance on fossil energy, it's needed to develop a more sustainable alternative way.

Recently, a research team led by Prof. ZHANG Tao, Prof. WANG Aiqin and Prof. LI Ning, in collaboration with Prof. WANG Feng's group, from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) developed a sustainable route for the production of copolyester monomers with biomass.

This study was published in Angewandte Chemie International Edition on Nov. 30, and it was selected as Hot Paper.

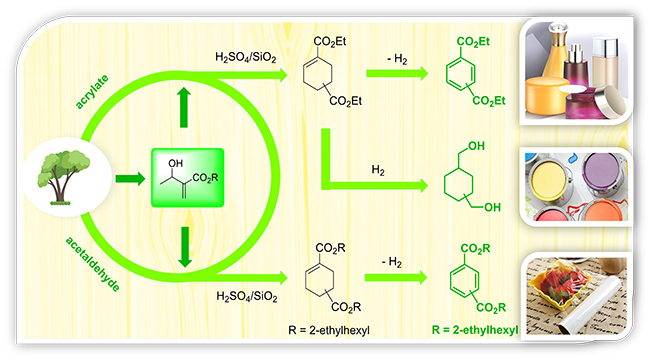

A flow diagram for the production of monomers with acetaldehyde and acrylate (Image by YUAN Lin)

In this study, the researchers used plant-based acrylate and acetaldehyde as feedstocks, and produced PCTA monomer in an overall yield of 61%. The whole process included Morita–Baylis–Hillman (MBH) reaction, one-step dehydration/Diels–Alder reaction, and final Pd/C-catalyzed dehydrogenation.

Besides, they varied the final step to hydrogenation over Pd/C-Cu/Zn/Al dual-bed catalyst, and produced UNOXOLTM diol, which is another important monomer in coatings industry, in an overall yield of 67%.

Furthermore, the life cycle assessment implied that the newly-developed biomass-based routes had the potential to reduce carbon footprint.

"This study paves a new way for the production of renewable PCTA and also provides a new guidance for biomass conversion," said Prof. LI.

This work was supported by the Natural Science Foundation of China and Joint Fund of Yulin University and Dalian National Laboratory for Clean Energy. (Text by LIN Yuan and HU Yancheng)