Original breakthroughs in chemistry and materials science have taken the first prizes of the 2020 State Natural Science Award, the nation's highest academic accolade for basic sciences.

One of the winning team is led by Prof. BAO from the Dalian Institute of Chemical Physics of the Chinese Academy of Sciences in Liaoning province.

As a key technology, catalysis has played an essential role in the fields of energy conversion, material synthesis, environmental protection, life and health. Precise control of chemical reaction has been a dream of scientists. This becomes particularly important under the current quests for highly efficient conversion of energies, optimized utilization of natural resources and ecological/environmental protection. It requires chemical reactions to be operated under milder conditions, to be more precisely and efficiently controlled. Therefore, the catalysis science and technology is confronted with grand challenges and opportunities for innovations.

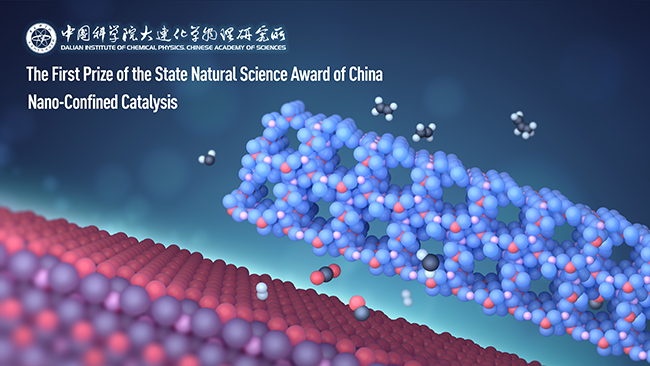

Since the middle of the 1990s, Prof. BAO Xinhe from the Dalian Institute of Chemical Physics of the Chinese Academy of Sciences has been leading his research team and being devoted to the fundamentals and applications of nanocatalysis, pursing for deep understanding of catalytic processes and rational design of advanced catalysts. With the systematic experimental and theoretical studies over more than 20 years, they have developed a new concept of "Nano-confined Catalysis", which covers confinement effects within nanospaces and at interfaces.

The "Nano Confinement" is essentially the driving force to generate and stabilize the coordinatively unsaturated active sites and to maintain the catalytic cycles. This generalized concept provides a theoretical guidance for rational design of nanocatalysts, and modulation of activity and selectivity of reactions, for instance, selective oxidation and hydrogenation reactions.

The team has a few catalysts and catalytic processes gone through industrial pilot scale tests. One representative example is the Pt-FeO nanocatalyst they have designed, containing coordinatively unsaturated metal sites, which enables removal of 30 ppm CO in H2 feed gas down to 1 ppm in commercial fuel cells for over 3500 h. This provides a solution for the long-standing deactivation problem of Pt electrocatalysts in fuel cells due to poisoning of CO.

Another representative example is the OXZEO? catalytic system, by integrating interface and nanospace confinement effects. The coordinatively unsaturated active sites at the oxide/oxide interfaces of partially reduced mixed oxides allow activation of CO/H2 to form active intermediates, while the shape selective nanopores of zeolites allow controlled C-C coupling. Thus, coal-derived syngas (a mixture of CO and H2) is converted directly in one step to light olefins, i.e., ethylene, propylene and butane with a selectivity reaching 80%. This surpasses the selectivity limit of 58%, a challenge in the conventional Fischer-Tropsch synthesis, which was invented almost a century ago. Furthermore, water-gas-shift reaction for hydrogen production can be discarded in this OXZEO?-TO process and thus H2O-H2 recycling is not needed. In addition, the team has extended this OXZEO? catalyst design concept for direct conversion of syngas to a series of other chemicals and fuels, making significant contribution to the coal chemical industry.