The full integration of miniaturized energy harvesters, energy storage and energy consuming devices into a self-powered integrated micro-system on a single substrate is promising in flexible electronics applications.

Printing techniques exhibited great potential for integrated circuits and targeted functional devices. Screen printing enables scaling with high throughput, but it faces the challenge of fabricating multitasking ink.

Recently, Prof. WU Zhongshuai's group and Prof. LIU Shengzhong's group from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences developed aqueous printable multitasking MXene inks, which were applied as additive-free high-capacitance electrodes, sensitive pressure-sensing materials, highly conducting current collectors, metal-free interconnectors, and conductive binders.

This study was published in Advanced Materials on Feb. 1.

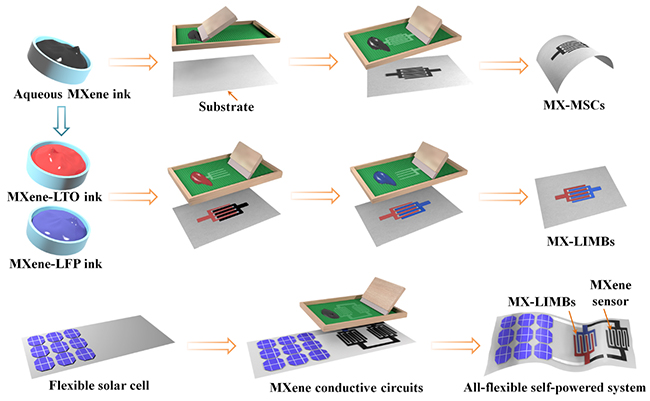

Schematic of the fabrication of printable microelectrochemical energy storage devices and all-flexible self-powered integrated system (Image by ZHENG Shuanghao)

The researchers constructed MXene-based MSCs (MX-MSCs) and lithium ion micro-batteries (MX-LIMBs) via screen printing in a versatile and scalable manner on various substrates, including A4 paper, wood, fabric, SiOx-coated stainless steel, etc.

Notably, the MX-MSCs delivered ultrahigh areal capacitance of 1.1 F/cm2 and energy density of 13.8 μWh/cm2, both of which were much higher than most reported MX-MSCs. And a highly integrated MSCs pack consisting of 100 serially-connected MX-MSCs output a high voltage of 60 V, which were the highest value for MX-MSCs so far.

Furthermore, the quasi-solid-state MX-LIMBs, composed of only active materials and MXene, presented an increased areal energy density of 154 μWh/cm2.

The researchers also developed an all-flexible MXene-based self-powered integrated system, composed of a tandem thin-film silicon solar cell, a MX-LIMB, and a MXene hydrogel pressure sensor on a flexible co-planar substrate. And it was demonstrated that sensitively monitors of the system for the bending of body parts had a fast response of 35 ms.

This work was supported by National Natural Science Foundation of China, Dalian National Laboratory for Clean Energy of CAS, etc. (Text by ZHENG Shuanghao and HOU Xiaocheng)