Fluidized catalytic cracking (FCC) and hydrocracking are the most important processes in the petroleum refining industry. High silica zeolite Y with FAU topology is the main active component for industrial cracking catalysts, which consumption ranks the first in the solid catalysts.

However, the physique of Al-rich framework of zeolite Y brings a fatal drawback in hydrothermal stability toward its practical applications. To alleviate this issue, repeated dealumination processes have been employed in order to achieve the high silica counterparts.

These post-treatment procedures are complicated and time/energy-consuming. Over the past 60 years, the direct synthesis of high silica Y remains a symbolic challenge in the field of zeolite synthesis, with a limited improvement of SiO2/Al2O3 ratio (SAR) from ~5 to 9.

Recently, a group led by Prof. TIAN Peng and Prof. LIU Zhongmin from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences developed a new strategy to directly synthesize high silica zeolite Y with SAR as high as 15.6. The results were published in Adv. Mater.

NOA-co strategy and novel OSDAs for the synthesis of high silica zeolites Y (Image by WANG Linying and ZHU Dali)

The novel strategy, named NOA-co strategy, involved the use of highly dispersed FAU nuclei solution, bulky organic structure directing agent (OSDA) and low alkalinity synthetic gel.

The researchers discovered a series of quaternary alkylammonium ions as effective OSDAs, and elucidated the relevant crystallization mechanism.

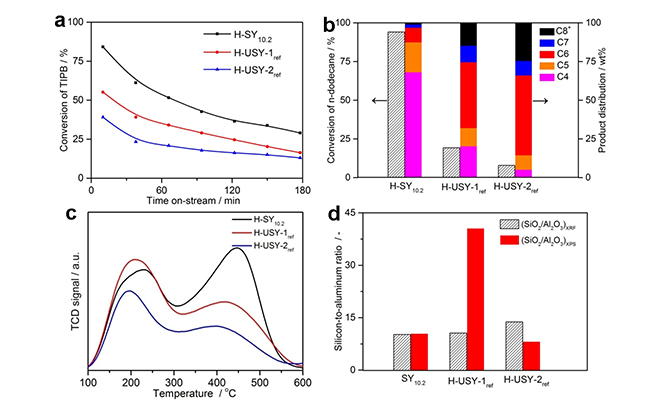

Catalytic cracking performance, acidity and Al distribution of high silica zeolite Y (Image by WANG Linying and ZHU Dali)

High silica zeolite Y synthesized by NOA-co strategy is featured with particle size of 100 to 250 nm, well-developed pore structure and excellent thermal/hydrothermal stability. Compared with the ultra-stable Y obtained by post-treatment, it has more strong acid sites and uniform acid distribution, which leads to superior catalytic performance in the cracking of bulky hydrocarbons.

This work was supported by the National Natural Science Foundation of China, the Key Research Program of Frontier Sciences, and DICP Funding. (Text by WANG Linying and ZHU Dali)