A research group led by Prof. ZHANG Huamin, Prof. LI Xianfeng and Prof. ZHANG Hongzhang from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. WANG Qingsong from the University of Science and Technology of China, developed a "Giving comes before receiving" pre-lithiation strategy for Li-ion battery (LIB).

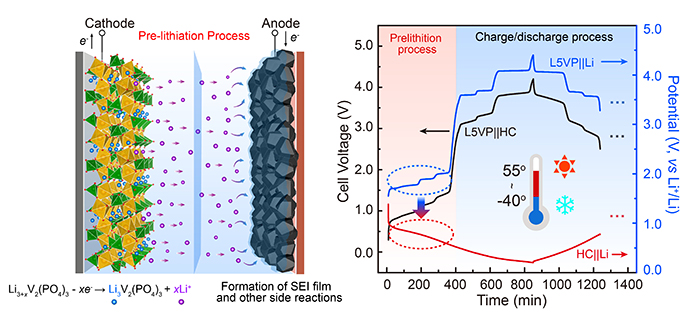

Schematic of the pre-lithiation process of L5VP||HC full cell. (Image by SONG Zihan)

The performance of LIBs in a wide temperature range, especially at very low and high temperatures, is directly restricted by their cathode and anode materials. Graphite is widely used as the anode material for commercial LIBs but suffers obvious performance failure if operation temperatures decrease.

Hard carbon (HC) exhibits outstanding Li storage performance at low temperatures. However, during the initial lithiation process of HC, the formation of solid electrolyte interphase (SEI) and certain by-products irreversibly consumes Li, leading to loss of capacity in the battery.

Pre-lithiation is a common strategy to solve above issues. More effective and safer pre-lithiation method remains to be studied.

The scientists proposed the Li5V2(PO4)3 (L5VP) cathode to match the HC anode based on a "Giving comes before receiving" strategy.

L5VP was firstly obtained by lithiating Li3V2(PO4)3 (L3VP) as the "giving" step, and then the irreversible capacity loss of HC was entirely compensated by de-lithiation of L5VP below 3.0 V (vs. Li+/Li). As a result, the L5VP||HC pouch full cell exhibited a high specific energy of 320 Wh/kg at room temperature. Especially, it could charge and discharge at -40°C with 80% capacity delivery.

According to in-situ characterizations and thermal analysis methods, L5VP showed a stable phase transition behavior and the minimum heat release during lithium insertion/extraction, indicating a good safety.

Moreover, that full cell design offers a feasible method of a great potential to realize advanced wide temperature range LIBs.

The above results were recently published in Nano Energy. This work was supported by DICP, Dalian National Laboratory for Clean Energy, National Natural Science Foundation of China, Youth Innovation Promotion Association of CAS, Dalian Science and Technology Star Program. (Text by SONG Zihan)