The rapid development of miniaturized, flexible and wearable electronic devices has essentially stimulated the urgent demand of microscale power sources that can be directly integrated with them. Micro-supercapacitors (MSCs) with impressive power density, large storage capacity, and superior cycling lifetime are arising as a class of next-generation on-chip energy storage devices. In general, graphene-based MSCs are created by conventional lithographic microfabrication, inkjet printing, screen printing, laser-irradiation assisted method.

However, these techniques usually involve multiple separated steps, resulting in the complicated processes, high cost, relatively low power density, poor frequency response and low efficiency of device assembly in a large scale. As a result, developing inexpensive, single-step scalable fabrication of MSCs with both high energy and power densities is still challenging.

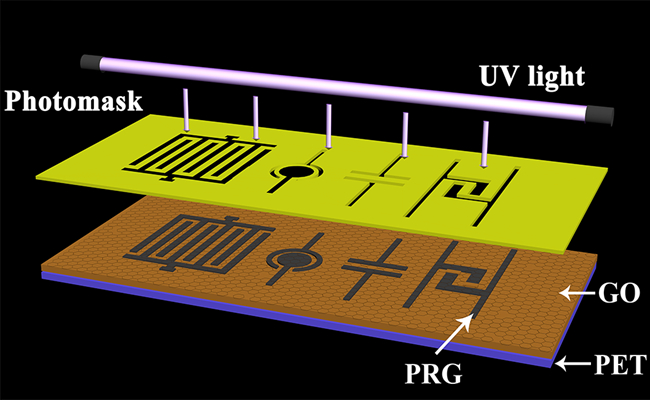

Schematic diagram showing the one-step fabrication process for PRG-MSCs with different geometries of parallel interdigital, concentric circular, two parallel strips and folding line fingers (Imaged by WANG Sen and ZHAO Xuejun)

To solve this issue, the scientists WU Zhongshuai, SUN Chenglin, BAO Xinhe et al from Dalian Institute of Chemical Physics developed the scalable fabrication of graphene-based monolithic MSCs with diverse planar geometries and capable of superior integration by photochemical reduction of graphene oxide/TiO2 nanoparticle hybrid films. This work has been published online in ACS Nano (DOI: 10.1021/acsnano.7b01390).

The as-fabricated MSCs displayed high volumetric capacitance of 233.0 F cm-3, outstanding flexibility, and remarkable capacity of modular serial and parallel integration. More importantly, by precisely engineering the interface of electrode with electrolyte, they developed high-rate graphene-based MSCs using a hydrophobic electrolyte of ionic liquid, working well at a high scan rate of 200 V s-1, two orders of magnitude higher than those of conventional supercapacitors. The MSCs showed high volumetric power density of 312 W cm-3 and energy density of 7.7 mWh cm-3, both of which are among the highest values achieved for carbon-based MSCs. More importantly, this method is highly flexible for tailoring the geometries and sizes of MSCs, and make modular integration without need of additional metal-based interconnects and contacts. Therefore, this inexpensive, single-step photoreduction strategy holds great potential for scalable production of cost-efficient, flexible and miniaturized graphene-based MSCs. (Text and Image by WANG Sen and ZHAO Xuejun)

Funder: This work was financially supported by the National Natural Science Foundation of China (Grant 51572259), National Key R&D Program of China (Grants 2016YBF0100100, 2016YFA0200200), Natural Science Foundation of LiaoningProvince (Grant 201602737), and DICP (Grant Y5610121T3).

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn