With the dramatic developments of flexible and wearable electronics, a future energy storage device concentrates on the continuous miniaturization and diversified integration of micro-scale power sources. However, the conventional energy storage devices, such as lithium ion batteries and supercapacitors, are usually configured with sandwich-like stacked geometries. They poorly miniaturize in size and are not well compatible with planar integrated circuits on single substrate. Therefore, the supercapacitors with multiple functionalities, flexibility, miniaturization, planarization and integration are urgently considered in the developing process of electronics.

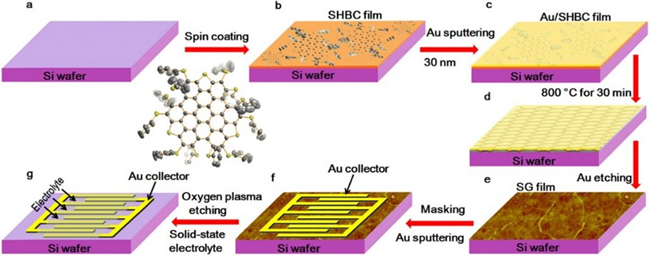

Schematic illustration of SHBC-derived SG films for planar MSCs on a Si/SiO2 wafer. (Image by ZHAO Xuejun)

To achieve this goal, the scientists WU Zhongshuai and BAO Xinhe et al from Dalian Institute of Chemical Physics, and their cooperative scientists from Germany and UK, reported the bottom-up fabrication of continuous, uniform, ultrathin sulfur-doped graphene films derived from sulfur-annulated nanographene for ultrahigh volumetric capacitance Micro-Supercapacitors (MSCs). This work has been published online in high-profile Journal of the American Chemical Society (DOI: 10.1021/jacs.7b00805).

The wafer-scale sulfur-doped graphene (SG) film was produced by thermal annealing of the spray-coated sulfur-annulated nanographene film under a thin Au protecting layer, at 800 oC for 30 mins. Remarkably, their planar MSCs presented outstanding pseudocapacitive behavior (~582 F cm-3), excellent rate capability (8.1 F cm-3 even at ultrahigh rate of 2000 V s-1), extremely short time constant (0.26 ms), and ultrahigh power density (~1191 W cm-3). By using nanographene molecule as precursor, this fabrication strategy provided a new scaffold for constructing large-area carbon films with assistance of a thin Au layer as 2D confining cover. Meanwhile, the as-produced SG film will offer numerous opportunities as an outstanding carbon-based material for advanced supercapacitors, metal-free oxygen reduction catalysts, batteries, and sensors. (Text and Image by ZHAO Xuejun)

Funder: The National Natural Science Foundation of China (Grant 51572259), Ministry of Science and Technology of China (Grant 2016YBF0100100 and 2016YFA0200200), Natural Science Foundation of Liaoning Province (Grant 201602737), DICP (Grant Y5610121T3), China Postdoctoral Science Foundation (Grant 2016M601349), dedicated funds for methanol conversion from DICP.

Dr. LU Xinyi

Dalian Institute of Chemical Physics, Chinese Academy of Sciences,

457 Zhongshan Road, Dalian, 116023, China,

Tel: 86-411-84379201

E-mail: luxinyi@dicp.ac.cn